Advantages of 3D printed prototypes

3D printed prototyping is an innovative manufacturing method that creates three-dimensional objects by stacking materials layer by layer. Compared with traditional manufacturing methods, 3D printing has many unique advantages. This article will introduce several main advantages of 3D printing.

1. Rapid prototyping

We often say that the advantage of 3D printing technology is that the batch size is small and can be customized according to needs. Compared with large-scale prduction in traditional factories and production lines, the advantages are naturally reflected. 3D printing technology can quickly produce product prototypes, and designers can shorten the development cycle and improve the accuracy of product design through iterative design.

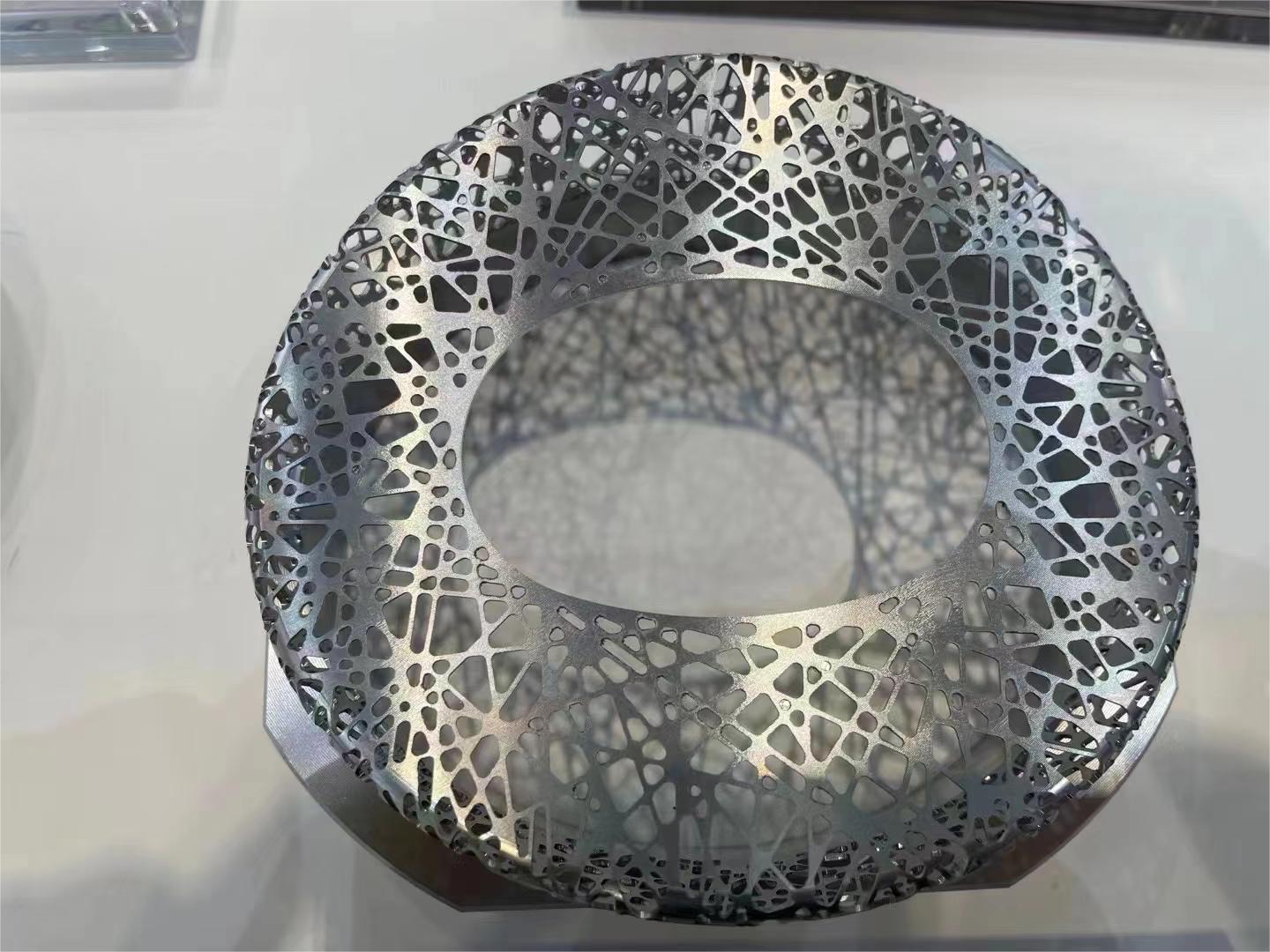

2. Complex geometric shapes

Diversified production will not increase costs. As far as traditional manufacturing is concerned, the more complex the shape of the object, the higher the manufacturing cost. 3D printing technology can easily realize complex geometric shapes, allowing designers to create unique products and components and achieve higher Creative freedom, relatively low cost.

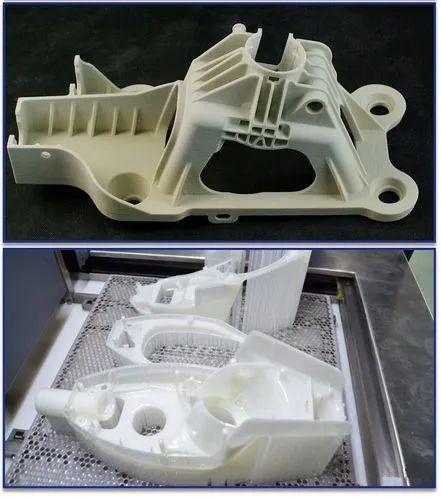

3. Small batch production

Small batch prototypes can bring new products to the market through small batches and customization, thereby reducing the risks caused by mass production and reducing corporate costs.

4. Prototype innovation

3D printing technology offers tremendous opportunities for innovation due to its flexibility and design freedom. Designers can more easily try new shapes, structures and materials, which helps designers and engineers conduct multiple repeated inspections and truly experience the appearance and feel of the product, thus promoting product innovation. In addition, 3D printing technology also supports rapid iteration and prototyping, greatly shortening the product development cycle and promoting the acceleration of innovation.

5. Personalized customization

An important advantage of 3D printing technology is that customized products can be manufactured according to individual needs. Personalized products can be manufactured according to customer needs and preferences to provide a better user experience.

6. Sustainability and resource conservation

3D printing technology has great advantages in material utilization. Traditional manufacturing methods often produce large amounts of waste materials and by-products, resulting in a waste of resources. The use of 3D printing technology can accurately control the amount of materials used as needed and reduce the generation of waste. In addition, by using renewable and recycled materials, 3D printing technology can further reduce the impact on the environment and improve sustainability.As 3D printing technology further matures, 3D printing technology will gradually break the bottleneck of traditional manufacturing technology encountered by people, and the future is full of infinite possibilities.