Application of CNC machining in aerospace industry

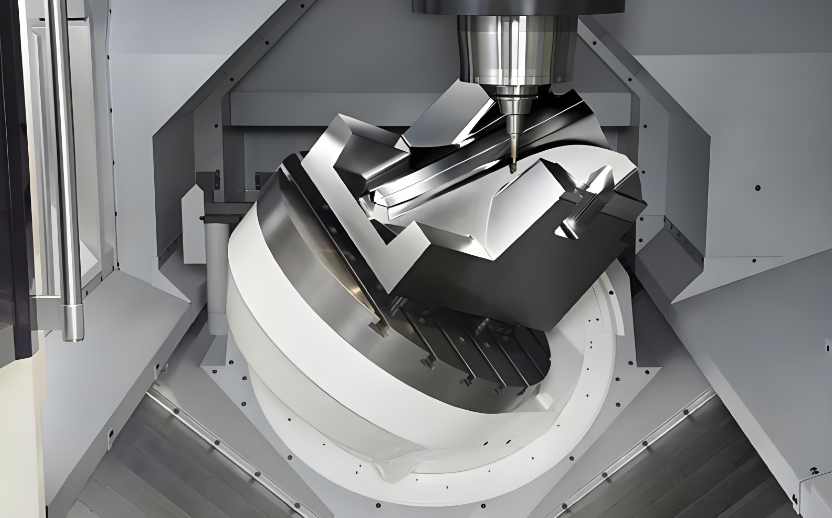

CNC, or computer numerical control, is a manufacturing technology that uses computer-controlled machine tools to perform operations such as cutting, punching, drilling, milling, turning, and grinding. It can accurately control the processing process through digital control instructions to achieve high-precision and high-efficiency processing.

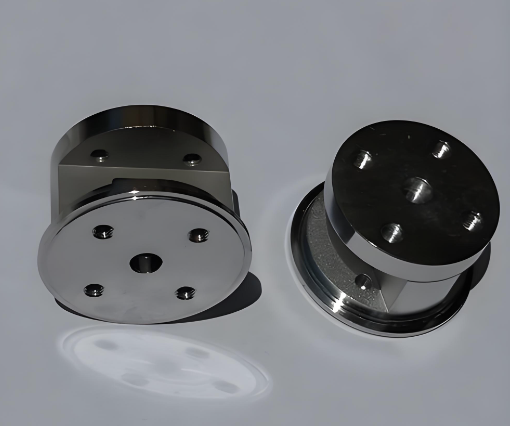

In the aerospace industry, the application of CNC machining technology has significant advantages. First of all, CNC machining technology can realize the processing of high-precision parts and ensure the consistency of parts. Due to the automatic control and tool positioning capabilities of CNC machine tools, each part can be processed according to the same program, thus avoiding errors and inconsistencies in manual operations. This is crucial for the aerospace industry, as high-precision parts are key to ensuring the safe flight of aircraft, rockets and other aircraft.

Secondly, CNC processing technology can improve production efficiency and reduce production costs. Traditional machining requires a lot of manpower investment and a long production cycle, while CNC machine tool processing can reduce manpower investment, shorten the production cycle, and avoid human errors and waste. This enables aerospace companies to respond more quickly to market demands and improve competitiveness.

In addition, CNC machining technology provides the aerospace industry with greater innovation and design freedom. Engineers can use CNC machine tools to process based on CAD models, allowing them to design and manufacture more flexibly and achieve more diverse and complex parts and structures. This is of great significance for promoting the progress and development of aerospace technology.

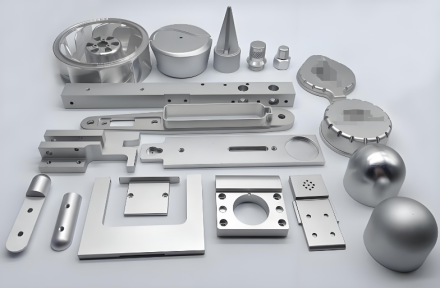

Accuracy is critical to the safe and reliable operation of aviation equipment, from commercial and private aircraft to starships. Some applications that benefit from the increased precision of aerospace machining services include:

1. Spacecraft parts

High-performance spacecraft components such as robotic arms, electrochemical systems, pipes, and casings are manufactured using precision CNC machining. Every component used in a spacecraft must be lightweight, durable, and resistant to the temperatures and radiation exposure common in the space environment.

2. Body design

Aircraft and spacecraft airframe design is critical for movement, speed and efficiency. CNC machining helps ensure exterior panels and surfaces fit together seamlessly for optimal aerodynamic configuration.

3.Engine parts

Aircraft and spacecraft engines operate under extreme pressures, and the components of these engines must be able to withstand very high operating temperatures as well as the freezing temperatures common in the upper atmosphere and space. Engine components must be extremely precise to ensure safe and reliable engine operation.

4. Communications and computer system parts

Aerospace equipment relies heavily on computer and communication systems for life support, ventilation, navigation, engine control, motion control, actuators and a variety of other critical applications. CNC machined components keep these vital systems running smoothly and efficiently.

5.External components

Aerospace equipment has a variety of external components including flaps, lights, sensors and external panels. To withstand the harsh conditions of air and space travel, these components are often made from high-strength, lightweight materials that are easy to machine using CNC manufacturing equipment.

6. Landing gear

Landing gear is critical to ensuring safe takeoff and landing for aircraft and some space shuttle designs. Aerospace CNC machining provides high-precision landing gear components for safe and reliable landing operations.

In general, the application of CNC machining technology in the aerospace industry not only improves the accuracy and consistency of parts, but also improves production efficiency and reduces production costs, providing strong support for the innovation and development of the industry. With the continuous progress and development of aerospace technology, CNC machining technology will continue to play an important role in promoting the sustainable development of the industry.