Metal 3D printing is rapidly emerging

Metal 3D printing is an additive manufacturing technology that is rapidly emerging and widely used in many fields. Here are some details about how metal 3D printers work, important benefits, and applications.

How metal 3D printers work

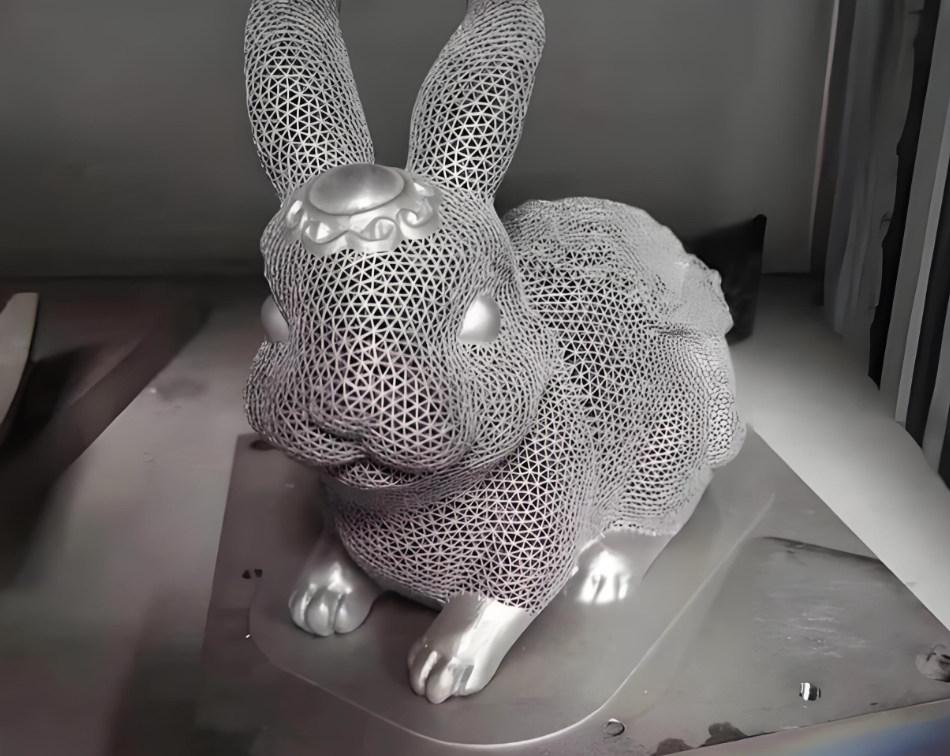

The working principle of metal 3D printers is mainly based on the method of depositing metal powder layer by layer. First, the required three-dimensional model is created through computer-aided design (CAD) software. The CAD model is then converted into slice files that describe each layer of detail in the model on a horizontal plane. During the printing process, metal 3D printers use laser beams, electron beams or other heat sources to melt or sinter metal powders, which are accumulated layer by layer according to the instructions of the slicing file, and finally form solid metal components.

Important advantages of metal 3D printing

1. High manufacturing efficiency: Metal 3D printing technology can produce complex metal parts in a short time without additional processing steps, thus greatly shortening the production cycle. The digital design process reduces manual intervention and improves manufacturing efficiency.

2. Cost reduction: By saving materials, reducing manual intervention and shortening the production cycle, metal 3D printing technology can reduce manufacturing costs. In addition, it enables better utilization of materials and reduces waste, further reducing costs.

3. Design freedom: Metal 3D printing technology can achieve highly complex designs, breaking the limitations of traditional manufacturing technologies. This gives designers greater creative scope to produce parts with unique shapes and functions.

4. Customized production: Metal 3D printing technology can carry out customized production according to customer needs to meet individual needs. This is particularly important in fields such as aerospace, medical and automotive.

Applications of metal 3D printing

1. Aerospace: Metal 3D printing technology is widely used in the aerospace field. It can create lighter and stronger components, improving aircraft fuel efficiency and performance. In addition, it can quickly manufacture accessories and spare parts that meet specific requirements.

2. Automobile manufacturing: In automobile manufacturing, metal 3D printing technology can be used to produce key components such as engine parts, transmission systems and braking systems. This helps improve the performance and safety of your car.

3. Medical: Metal 3D printing technology has great potential in the medical field. It can create products such as personalized medical devices, implants and prosthetics. In addition, it can provide doctors and researchers with more experimental platforms to conduct new medical research.

4. Construction: Metal 3D printing is considered an important technology in the future construction field. Through this technology, complex structures and parts can be manufactured, making construction more sustainable and efficient.

In short, metal 3D printing technology is rising rapidly with its unique advantages and is widely used in many fields. With the continuous advancement of technology and reduction of costs, it is believed that metal 3D printing will play a more important role in the future.