CNC machining technology in automobile manufacturing

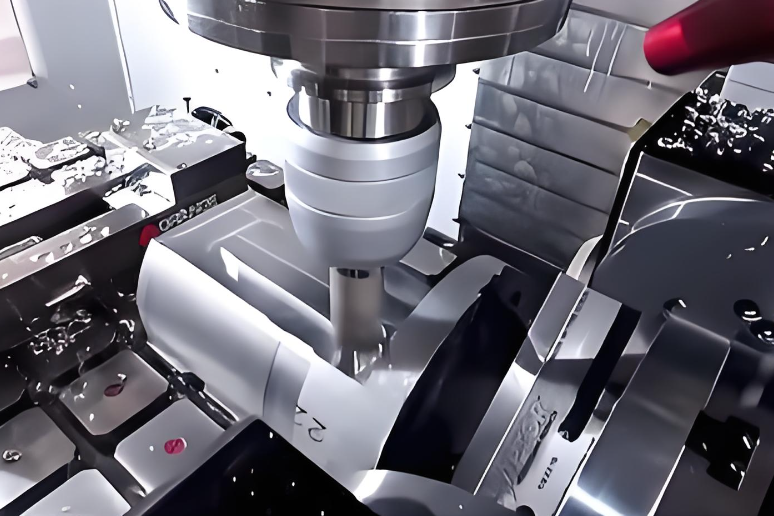

In automobile manufacturing, CNC machining technology plays a vital role. CNC, or computer numerical control, refers to the precise control of the movement of machine tools and tools through a computer control system to achieve high-precision processing of parts. The application of this technology in automobile manufacturing has significantly improved production efficiency, product quality and design flexibility.

First, CNC machining technology brings high efficiency to automobile manufacturing. Due to the high degree of automation of CNC machine tools, long-term, high-precision processing operations can be continuously performed, thus greatly improving production efficiency. At the same time, the multi-tasking capabilities of CNC machine tools also reduce the mold change and debugging time during the production process, further shortening the production cycle.

Secondly, CNC machining technology provides high precision for automobile manufacturing. CNC machine tools have high-precision positioning control capabilities, which can ensure that the size and shape accuracy of parts processed meet design requirements. This high-precision machining not only improves the quality of automobile parts, but also ensures the performance and safety of the entire vehicle.

In addition, CNC machining technology also enhances the design flexibility of automobile manufacturing. Traditional machining methods are often limited by equipment and processes, making it difficult to process parts with complex shapes. CNC machining technology can easily handle parts processing of various complex shapes and structures, providing automotive designers with greater creative space.

The applications of CNC machining technology in the automotive field include the following:

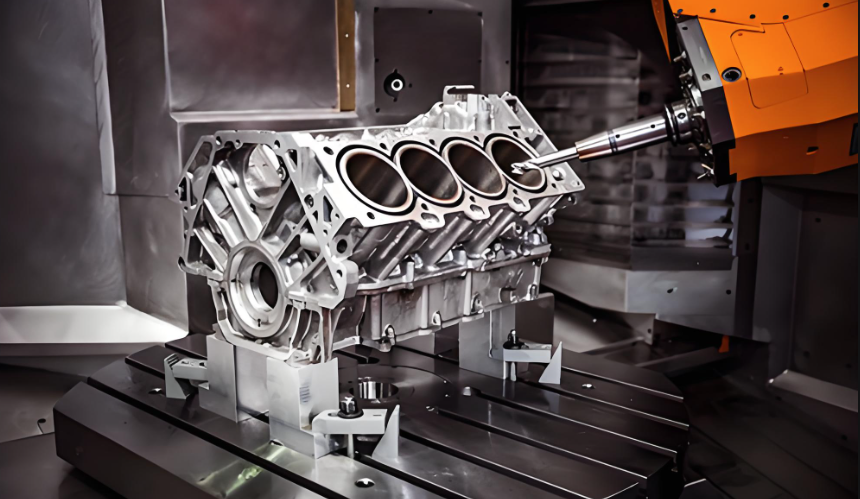

1. Engine components: CNC machining centers can accurately manufacture key components of the engine, such as crankshafts, camshafts, cylinder heads, and cylinder blocks. These parts require extremely high precision and surface quality, and CNC machining ensures they meet design requirements.

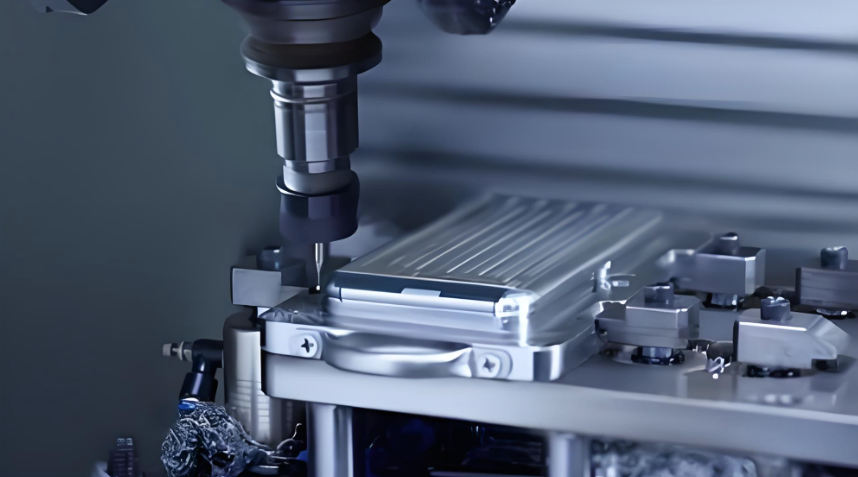

2. Traditional system components: Transmission system components such as gears, gear shafts and transmission shafts require precise tooth shapes and mating surfaces, and the high-precision cutting capabilities of CNC machining can meet these requirements.

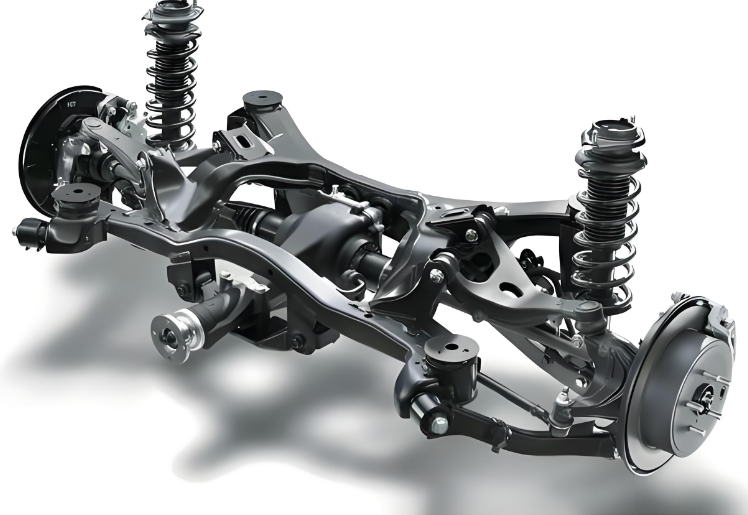

3. Suspension system components: Suspension system components such as steering knuckles and suspension arms have complex structures and require high-precision processing to ensure vehicle stability and safety. CNC machining can handle these complex structures and shapes.

4. Body structural parts: Body structural parts such as body frames and door hinges need to withstand the weight and vibration of the body, and have certain requirements for the strength and accuracy of the materials. CNC machining ensures the processing quality and accuracy of these parts.

5. Fasteners and connectors: CNC machining can also manufacture various automotive fasteners and connectors. These parts play a key role in automotive assembly and connections.

With the continuous development of CNC machining technology and the expansion of application fields, the application scope of CNC machining technology in automobile manufacturing is becoming more and more extensive. In the future, CNC machining technology will continue to play an important role in the field of automobile manufacturing.

We have focused on CNC machining in China for more than ten years, have 1SO9001:2015, and have many experienced engineers to ensure production and manufacturing, which can reduce production costs and increase profits for you. Our CNC machining accuracy can be as high as ±0.01mm, supporting product processing of copper, iron, aluminum, steel and various plastic materials. If you have any needs, please feel free to contact me.