3D printing services----medical industry

3D printing has taken the healthcare sector by storm over the past few years, be it surgery, pharmacology, dentistry or any other branch of industry. Medical 3D printing plays an active or passive role in improving processes, products and execution to help doctors save more lives. As time has passed and the technology has developed further, 3D printing in the medical field has now moved beyond its initial stages.Today, it has become an important pillar of modern medicine. From bioprinting 3D printed medical organs for transplantation to creating complex orthopedic implants, 3D printing continues to push the boundaries of what is possible in healthcare.

3D printed processing used in medicine

type

1.SLS

SLS uses a high-power laser to fuse small powder particles together to form a precise, durable structure. In the medical field, manufacturing custom implants and prosthetics is crucial.

2. SLA

SLA uses a laser to solidify liquid resin into a solid layer. It is ideal for producing highly detailed models for surgical planning and educational purposes.

3.FDM

FDM is one of the most cost-effective 3D printing technologies that can create excellent prototypes and custom tools for the medical industry. It relies primarily on heated nozzles to deposit thermoplastic material in layers to create the final shape.

4. Bioprinting

Bioprinting brings 3D printing into the realm of living tissue. It uses bioink loaded with living cells to create organs, tissues and structures, with huge potential in transplantation and regenerative medicine.

Materials used in medical 3D printing

Material selection in 3D printing is a key consideration as it affects the quality and safety of the final product. The following are the main categories of materials used in printed medical devices.

1.Polymer

Polymers such as PLA and ABS are common because of their flexibility and biocompatibility. This makes them suitable for creating prosthetics, anatomical models and patient-specific tools.

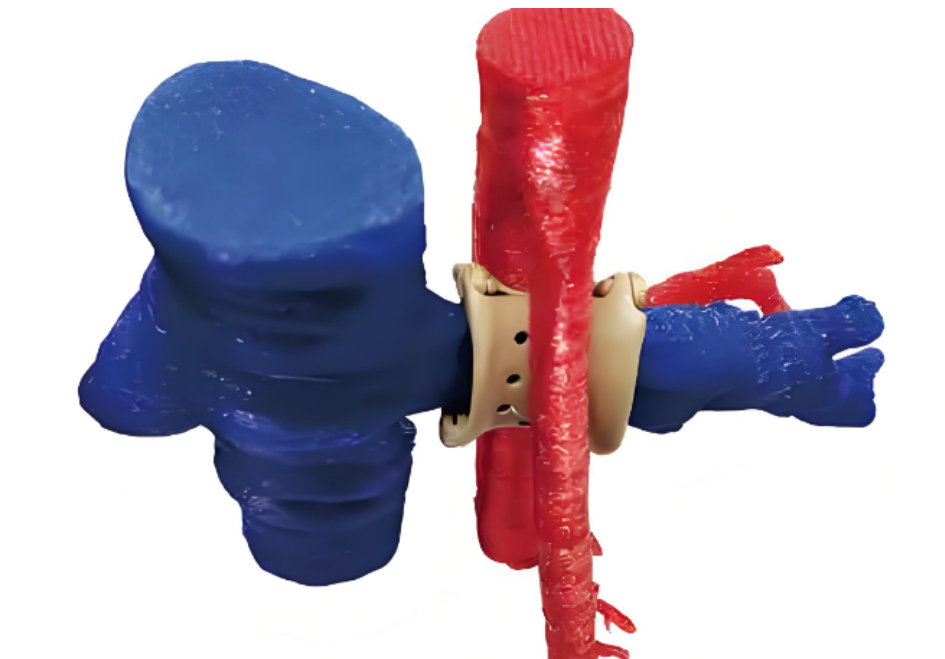

2.Metal products

Metal 3D printing involves titanium, stainless steel, cobalt-chromium alloy and other materials. These metals offer exceptional strength and durability, making them critical for orthopedic implants and dental applications.

3. Ceramics

Ceramic materials are biocompatible and resistant to high temperatures, making them ideal qualities for dental crowns, implants and even bone grafts.

4.Biological materials

Perhaps the most advanced and sophisticated 3D printing material as it allows for the use of artificial organs, tissues and other customized biocompatible solutions.

Application of 3D printing in medical industry

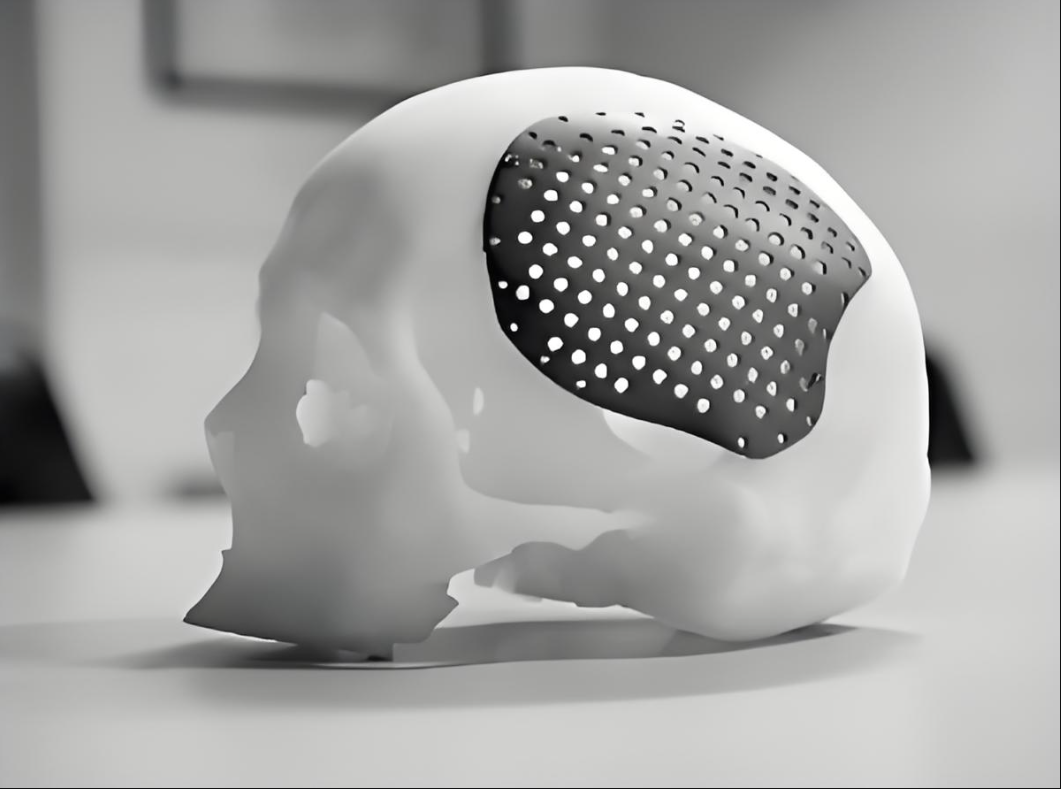

1. Surgical planning model

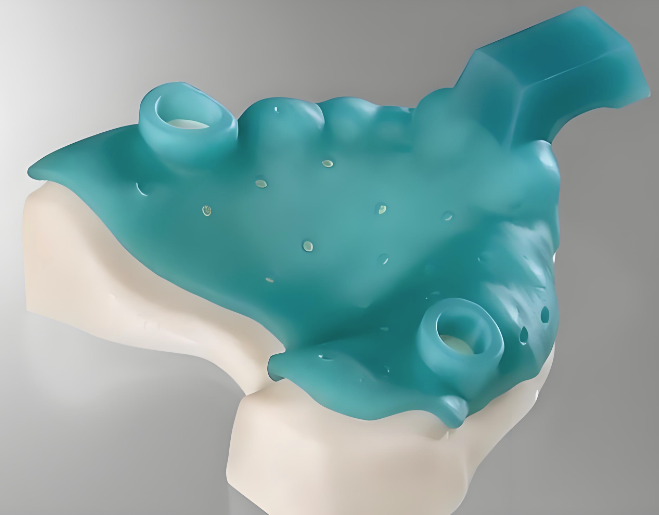

2. Surgical guide

3. Rehabilitation medical equipment

(3D printed metal hearing aids)

(3D printed wrist fixation brace)

(3D printed spinal orthosis)

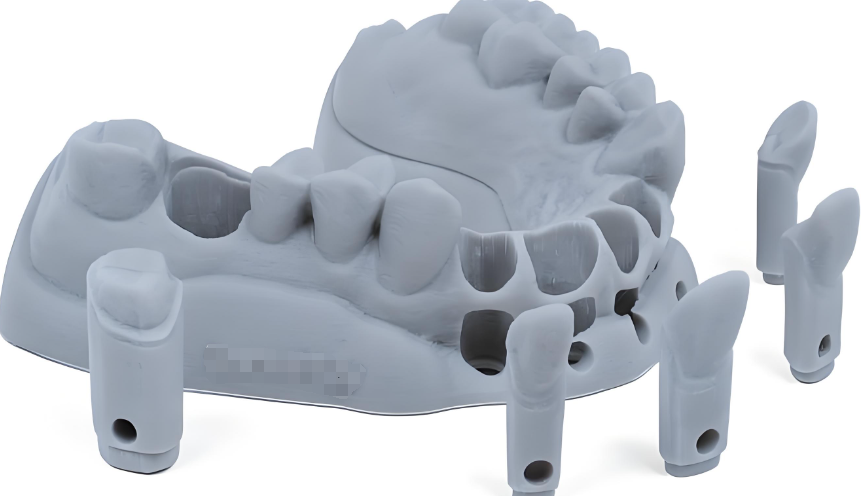

4. Orthodontics

5.Tooth restoration

3D printing technology is riding the wind and waves to open up new production models for various industries. Currently, 3D printing technology is injecting new vitality into the medical industry. In response to the increasing demand for customized treatments in the medical market, 3D printing is undoubtedly an indispensable and important part of the entire medical process.