Aerospace 3D printing applications

The aerospace and defense (A&D) industry is a great example of leveraging additive manufacturing, often referred to as 3D printing, with a clear value proposition of being able to create parts that are stronger and lighter than those manufactured using traditional manufacturing.

Common 3D printing use cases in aerospace

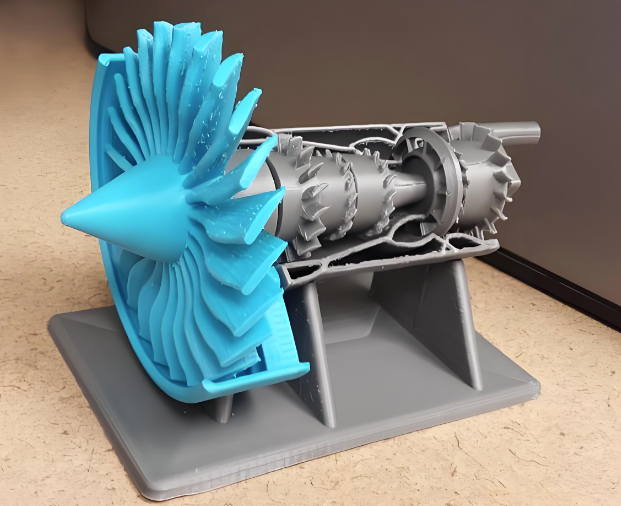

1. Parts manufacturing: 3D printing technology can directly produce complex parts according to design requirements, greatly shortening the manufacturing cycle. For example, key components such as stator parts, rotor parts and impellers of turbojet engines can be manufactured through 3D printing technology, and the performance of the manufactured parts can reach or even exceed the level of traditional processes. In addition, metal 3D printing technology is also used to manufacture parts made of high-strength materials such as titanium alloys. For example, GE Aviation Engine Company successfully printed complex combustion chamber parts. Compared with traditional processes, it not only reduces weight, but also has better performance. Excellent performance and high temperature resistance.

2. Manufacturing of chip radiator fixings: In the aerospace field, the heat exchange volume of chip radiators is large, which can easily cause the radiator to deform, affecting the heat dissipation effect and the service life of the chip. 3D printing technology can create fixings, such as tungsten to fix copper-based heat sinks, to solve this problem.

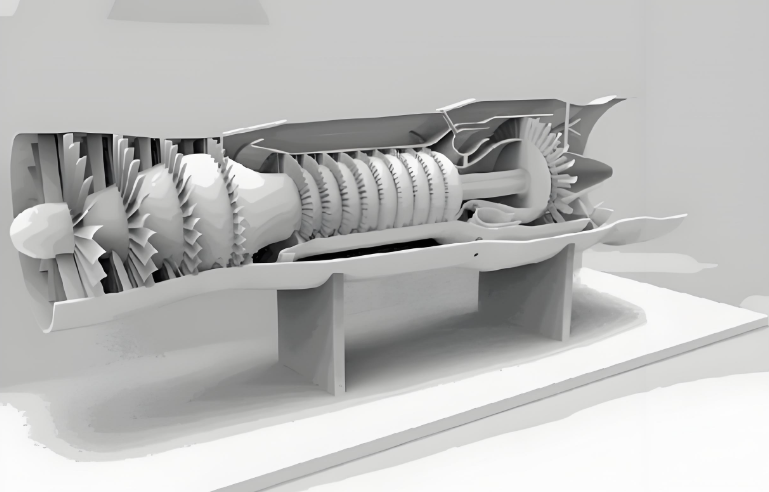

3. Model and prototype manufacturing: During the design and development process, the manufacturing of models and prototypes is critical to evaluate the feasibility and performance of the design. Traditional manufacturing methods often take a lot of time and cost, and may also contain errors. By using 3D printing technology, designers can quickly produce accurate models and prototypes according to needs, making testing and verification more convenient.

In addition to the specific use cases mentioned above, 3D printing technology is also used in other aspects of the aerospace field, such as manufacturing the exterior and interior of aerospace vehicles to improve comfort and visual experience.

In general, 3D printing technology is playing an increasingly important role in the aerospace field with its unique advantages, bringing new opportunities and challenges to the development of aerospace.

Several key things that must be paid attention to in aerospace

1. Material selection: Aerospace vehicles have extremely strict requirements on materials, which need to have good properties such as high temperature resistance, fatigue resistance, and corrosion resistance. When selecting 3D printing materials, you must ensure that their performance meets aerospace manufacturing standards and can withstand use under extreme conditions. At the same time, considering the lightweight requirements of aerospace vehicles, materials with low density and high strength need to be selected.

2. Process control: Process control during the 3D printing process has an important impact on the quality and performance of the product. Printing parameters, such as printing speed, temperature, layer thickness, etc., need to be strictly controlled to ensure that the dimensional accuracy, surface quality and mechanical properties of the printed parts meet the design requirements. In addition, the printing process also needs to be monitored in real time to detect and solve problems in a timely manner.

3. Design and modeling: In aerospace manufacturing, 3D printing technology is often used to manufacture complex parts and structures. Therefore, during the design and modeling stages, the functionality, structure, and printability of parts need to be fully considered. Avoid designing structures that are too complex or difficult to print to improve printing success rate and product quality.

4. Post-processing and inspection: After 3D printing is completed, a series of post-processing and inspection work are required. This includes grinding, polishing, heat treating, etc. to improve the surface quality and mechanical properties of your prints. At the same time, strict quality testing is also required to ensure that products meet the standards and requirements of aerospace manufacturing.

5. Safety and reliability: Aerospace manufacturing has extremely high requirements on product safety and reliability. Therefore, when using 3D printing technology, safety operating procedures must be strictly followed to ensure the safety of operators and equipment. At the same time, the printed parts also need to be fully tested and verified to ensure that they can meet the performance requirements of aerospace vehicles in actual use.

In short, when applying 3D printing technology to aerospace manufacturing, it is necessary to comprehensively consider factors such as materials, processes, design, post-processing and safety to ensure the production of high-quality, high-performance aerospace products.

About Us

Shenzhen Ruiyi Weiye Model Technology Co., Ltd. is a professional model company integrating design, production and production, focusing on small batch production of CNC processing and prototype manufacturing. We have advanced 3D printing technology and super post-processing technology, as well as an experienced and skilled model design and production team, aiming to provide the best microscopic expression for the model industry and promote the development level of the model industry. He has participated in the preparation of supporting parts for many units, and his product production capacity has been highly praised by the industry.

If you have any needs, please feel free to contact me.