What is 3D prototyping?

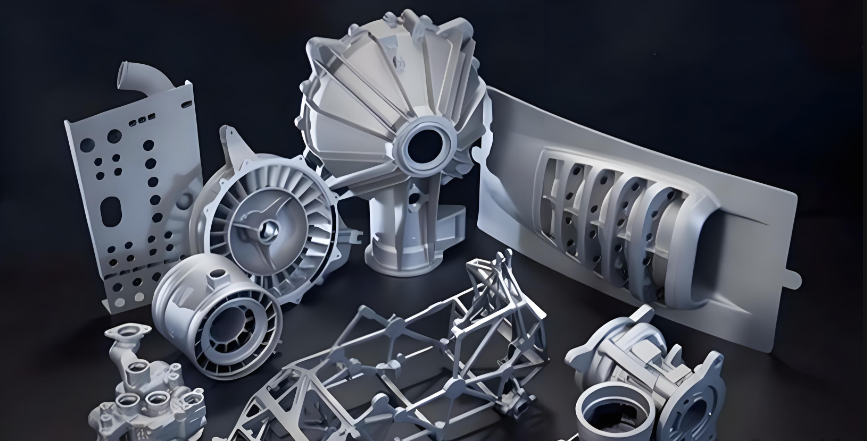

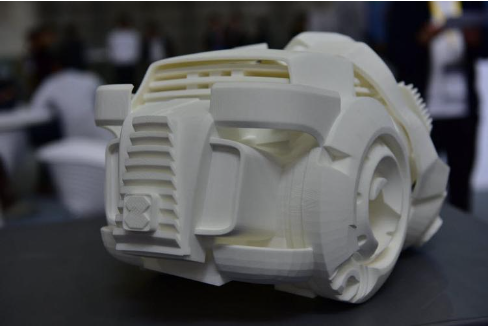

3D prototyping, also known as rapid prototyping, is an advanced manufacturing technology based on digital models. This technology converts digital models directly into physical models by stacking materials layer by layer. This manufacturing method can quickly and accurately produce various complex physical models, including product parts, models, samples, etc.

Unlike traditional subtractive manufacturing processes, 3D printing does not involve cutting blocks of material. In addition, it can produce complex shapes using less material. There are three main varieties of 3D printing, depending on the level of precision required. They include the following:

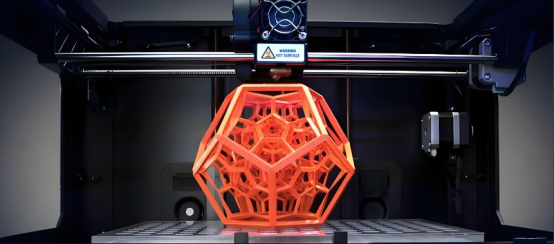

1. Fused deposition modeling (FDM). This 3D printing prototyping technology is the most popular and cost-effective option. It is easy to use and involves extruding thermoplastic filament layer by layer. This process grows quickly and is suitable for product development.

1. Fused deposition modeling (FDM). This 3D printing prototyping technology is the most popular and cost-effective option. It is easy to use and involves extruding thermoplastic filament layer by layer. This process grows quickly and is suitable for product development.

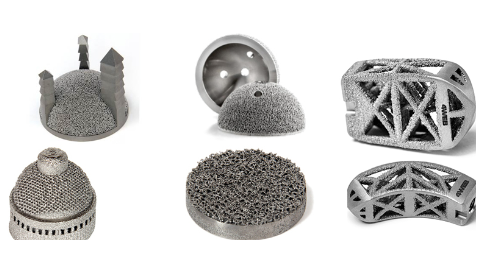

2. Selective laser sintering (SLS). This is a 3D printing technology used for plastic and metal prototyping. It builds prototypes using a powder bed layer by layer, using a laser to heat and sinter the powdered material.

3. Stereolithography (SLA). This method uses a jar of light-sensitive liquid resin to create a 3D prototype. Ultraviolet light (UV) then helps cure each layer of the product. This process continues until the model is complete. It is the recommended solution for high-resolution 3D prototypes.

Rapid prototyping 3D printers are valuable for manufacturing products ranging from mechanical parts and architectural models to jewelry designs and other consumer products.

Advantages of Rapid 3D Prototyping

3d prototyping technology is being adopted by several industries around the world as it offers several important advantages over traditional manufacturing techniques. These advantages include:

1.Design flexibility

3D printing technology can produce highly customized prototypes according to needs, and the shape, size and structure can be flexibly adjusted. This allows designers to quickly verify different design options and make necessary modifications and optimizations.

2. Save costs

While the initial investment in a 3D printer may be higher, rapid 3D prototyping is often less expensive in the long run than traditional manufacturing methods. Traditional prototyping methods may require expensive molds and tools, while 3D printing only requires a digital model and a printer. In addition, because 3D printing is manufactured on demand, it reduces the waste of materials, further reducing costs.

3. Save time

Rapid 3D prototyping can significantly shorten product development cycles. Traditional prototyping may take weeks or even months, while 3D printing technology can be completed in just hours or days, greatly improving the efficiency from design to production. This rapid prototyping capability enables designers and engineers to more quickly verify design ideas and perform iterative optimization, thus accelerating product time to market.

How to 3D print a prototype

The process of 3D printing prototypes can be briefly summarized as the following steps:

1. Design model: Use CAD software or other 3D modeling tools to design the prototype you want to print. You can create a model from scratch or use an existing model to modify and optimize.

2. Prepare model files: Save the designed model into supported file formats, such as .STL, OBJ, AMF, etc. You may also need to do some work on the model, such as fixing errors in the model, adjusting dimensions and proportions, adding support structures, etc.

3. Prepare printing materials and machines: Choose the appropriate printing materials and 3D printer according to your needs and budget. Different printing technologies and materials are suitable for different types of prototypes, such as FDM technology for plastic prototypes and SLA technology for prototypes with high precision and smooth surfaces.

4. Set printing parameters: Set printing parameters in the 3D printer software, including layer height, filling density, printing speed, etc. These parameters affect the quality and time of printing results.

5. Print the model: Load the prepared model file into the 3D printer and start the printing process. During the printing process, the print head stacks material layer by layer, gradually building a three-dimensional model. You need to monitor the printing process to make sure everything is running properly.

6. Post-processing: After printing is completed, you may need to perform some post-processing work, such as removing support structures, surface polishing, painting or other decorations, etc., to obtain the final prototype.

It should be noted that each printing technology and material has its own characteristics and scope of application, so when selecting and operating, reasonable selection and adjustment should be made based on the actual situation. In addition, it is also necessary to have a certain understanding and experience of 3D printing technology to ensure satisfactory printing results.

What are the best 3D materials for printing prototypes?

1. Nylon PA12

Nylon PA12 is a white plastic material that is one of the most affordable prototyping materials, has excellent mechanical properties, is ideal for prototyping and production runs, and is best suited for Selective Laser Sintering (SLS) technology.

2.Multi-jet fusion PA12

The material is a gray plastic ideal for prototyping and production. Weather-resistant, UV-stable and photostable, it's perfect for testing in outdoor conditions.

3.Prototype resin

Prototyping resin is more suitable for non-functional prototypes, perfect for manufacturing highly detailed components. It provides a smooth surface finish similar to products manufactured with plastic injection molding. This material is best suited for stereolithography (SLA).

4.PLA

PLA is a user-friendly material with high stiffness and strength. Not only is it one of the simplest 3D printing materials, it’s also an inexpensive material that can make reliable parts for many different applications. If aesthetics and detail are the main concerns, PLA is your material of choice.

5.TPU

TPU is the perfect solution for 3D printing prototypes of flexible plastics. This material has the properties of rubber, including high elasticity and high strength. So if you need something flexible, it will suit your prototyping projects. Parts made from this material are resistant to fatigue and stress, making them an excellent choice for the final product.

In conclusion

Rapid 3D prototyping is an efficient manufacturing process that enables faster and better engineering designs. It speeds up your workflow and eliminates bottlenecks in traditional prototyping cycles. Prototyping with 3D printing saves costs and reduces time to market while providing easier design testing and overall prototyping benefits.