Parts Finishing

Surface treatment is a process of modifying the surface of a workpiece to improve its corrosion resistance, mechanical properties, aesthetics or other specific properties. We use different post-processing methods based on customer requirements, materials, uses and manufacturing processes for different parts. The following are some common post-processing processes. If you have other post-processing requirements, please contact us for enquiries:

Surface treatment is a process of modifying the surface of a workpiece to improve its corrosion resistance, mechanical properties, aesthetics or other specific properties. Surface treatment is usually performed after the workpiece is manufactured to meet specific needs and requirements. Here are some common surface treatments:

1. Coating:

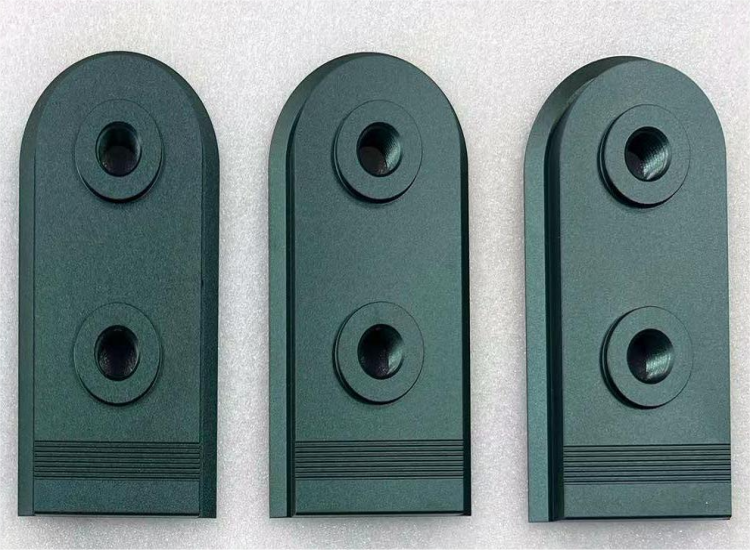

1) Spray Coating: Coating is evenly applied on the surface of the workpiece through a spray gun. Common coatings include paint, paint, anti-corrosion coating, etc.

2) Dip Coating: Dip the workpiece into paint so that the surface is evenly coated with paint.

3) Electroplating: Depositing a metal or alloy layer on the surface of a workpiece through electrochemical methods to improve corrosion resistance, aesthetics, or conductivity.

4) Thermal Spraying: Metal or ceramic powder is sprayed onto the surface of the workpiece through a high-temperature spray gun to form a covering layer to enhance wear resistance, heat resistance and other properties.

2. Chemical Treatment:

Pickling: Use acid solution to remove oxide scale, rust spots and other impurities on the surface of the workpiece to purify the surface.

Etching: Local etching of the workpiece surface through an acidic solution to create marks, patterns or improve surface roughness.

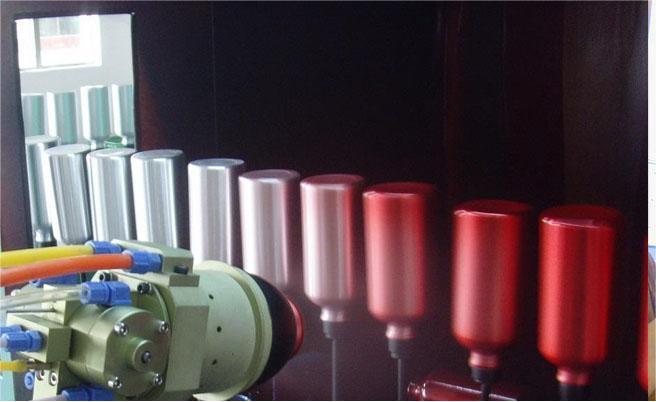

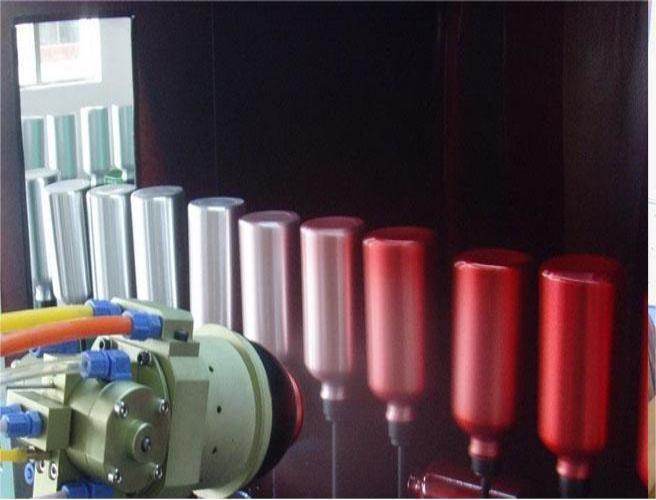

Oxidation (Anodizing): Forming an oxide layer on the metal surface to improve corrosion resistance, wear resistance and surface hardness.

3. Mechanical Treatment:

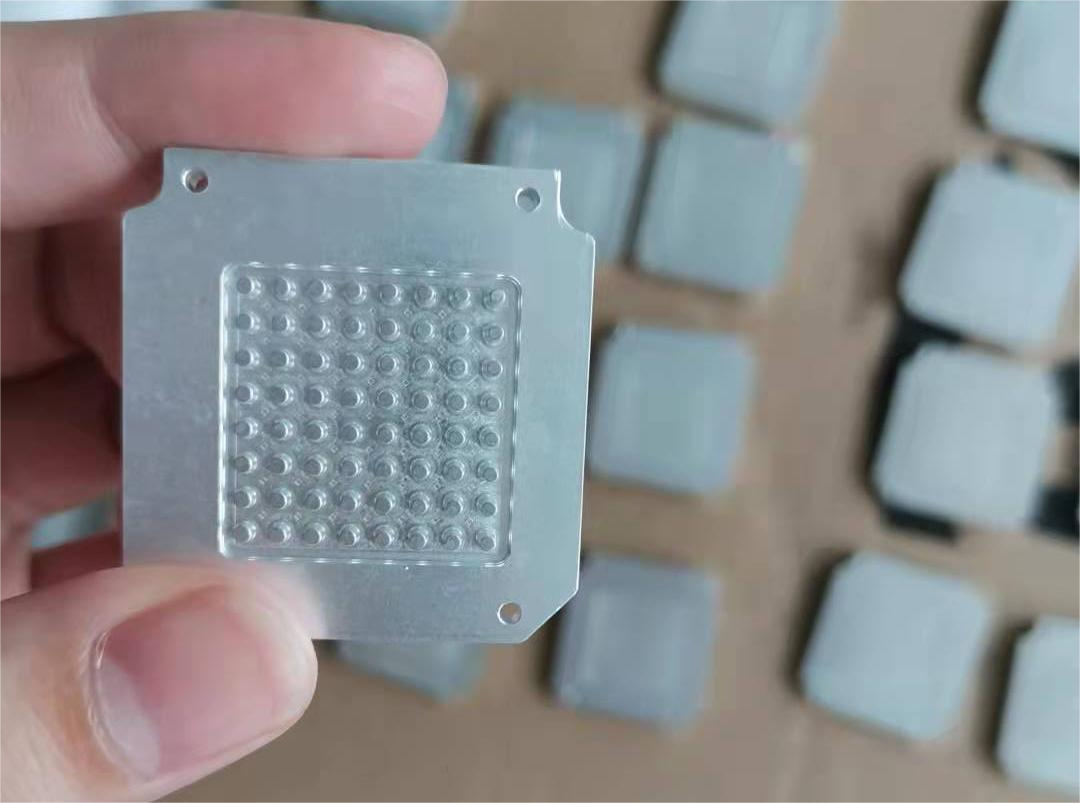

Polishing: Using abrasives to grind the surface of a workpiece to obtain a smooth, flat surface.

Grinding: Use a grinding wheel to grind the surface of the workpiece to improve surface roughness and flatness.

Buffing: Use a polishing machine or hand tools to buff the surface of the workpiece to improve the gloss and surface texture.

These surface treatment methods can be used alone or in combination. According to the characteristics, uses and requirements of the workpiece, the appropriate treatment method is selected to achieve the required surface properties and effects.