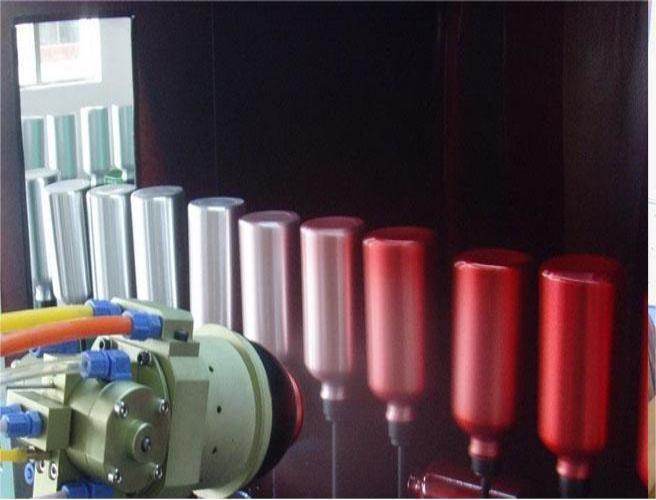

Passivation

Chromate film: It is a film formed by metal in a solution containing chromate. The film formation process is customarily called passivation in China.

The mechanism of passivation can be explained by the thin film theory, that is, passivation is believed to be due to the interaction between metal and oxidation properties. During the interaction, a very thin, dense, good covering performance, and firmly adsorbed on the metal surface is generated on the metal surface. Passivation film. This film exists as a separate phase, usually a compound of oxidized metals. It plays the role of completely separating the metal from the corrosive medium, preventing the metal from contacting the corrosive medium, so that the metal basically stops dissolving and forms a passive state to prevent corrosion.

Advantages of passivation:

1. Compared with the traditional physical sealing method, passivation treatment has the characteristics of absolutely not increasing the thickness of the workpiece and changing the color, improving the precision and added value of the product, making the operation more convenient;

2. Since the passivation process is carried out in a non-reactive state, the passivation agent can be added and used repeatedly, so the life is longer and the cost is more economical;

3. Passivation promotes the formation of an oxygen molecular structure passivation film on the metal surface. The film layer is dense and stable in performance. It also has a self-repairing effect in the air. Therefore, compared with the traditional method of applying anti-rust oil, the passivation formed by passivation Passivation film is more stable and corrosion resistant.