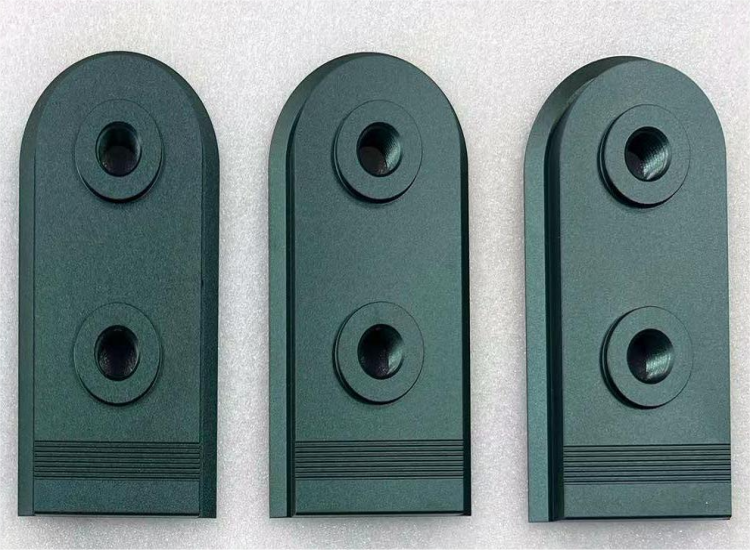

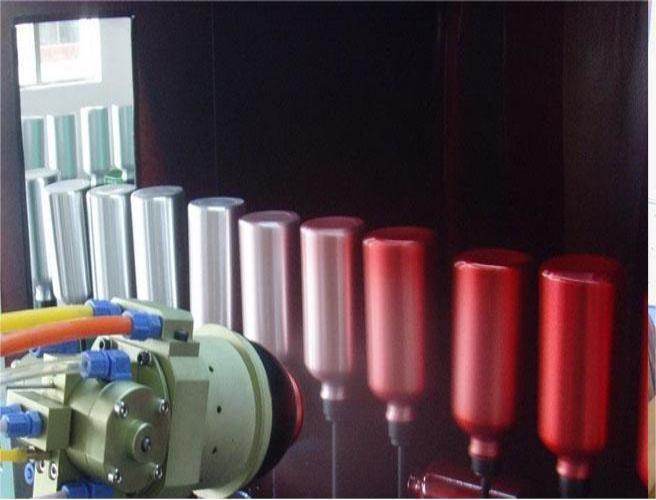

Anodized silver frosted aluminum

Sandblasting and anodizing is a sandblasting process + anodizing process, which means that the surface is first sandblasted and then oxidized. The aluminum parts are sandblasted and then oxidized with a matte finish.

The sandblasting process uses compressed air as power to form a high-speed jet beam, and sprays the spray material at high speed onto the surface of the workpiece to be treated, causing the appearance of the outer surface of the workpiece to change. Due to the impact and cutting effect of the abrasive on the surface of the workpiece, the surface of the workpiece becomes A certain degree of cleanliness and different roughness improve the mechanical properties of the workpiece surface.

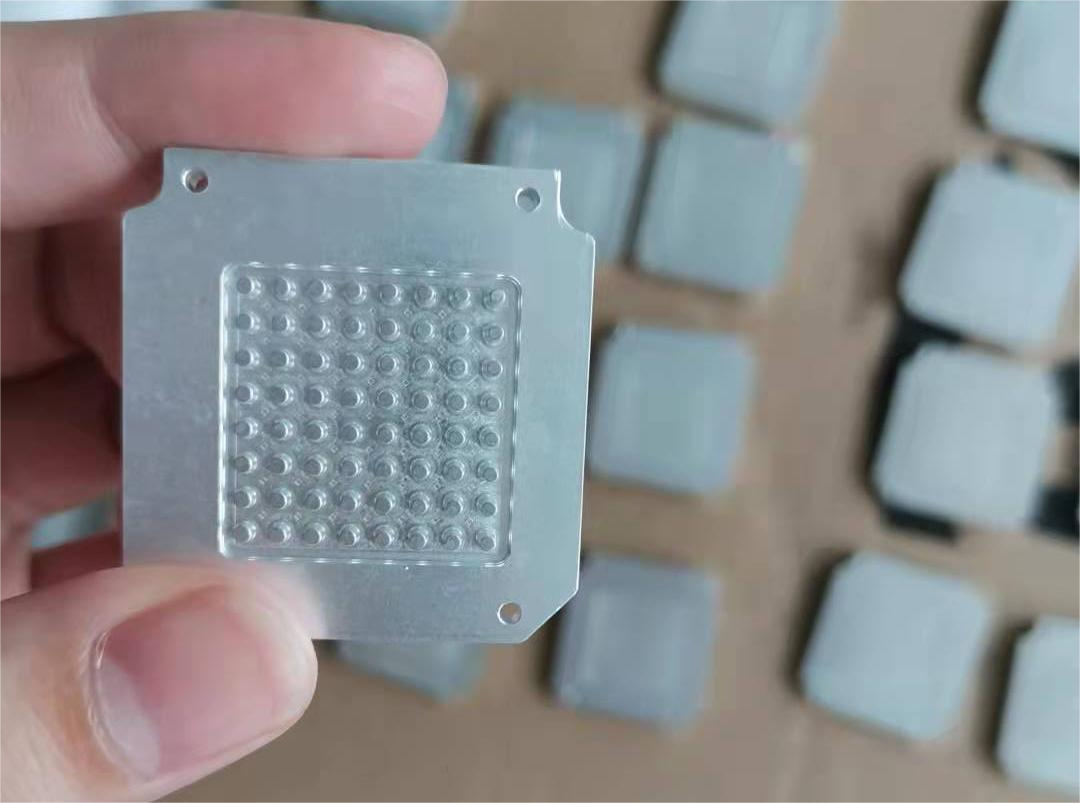

Characteristics of sandblasting process:

1. Sandblasting is the most thorough, most versatile, fastest and most efficient cleaning method.

2. Sandblasting can arbitrarily choose between different roughnesses, but other processes cannot achieve this. Manual polishing can produce a rough surface, but the speed is too slow. Chemical solvent cleaning will make the surface too smooth, which is not conducive to the adhesion of the coating. catch.

3. Sandblasting can increase the roughness and graininess of the surface, making the oxidized surface more uniform and delicate, and can hide some surface defects.