Drilling Stainless Steel

CNC machining is widely used in stainless steel, mainly due to the excellent properties of stainless steel and the flexibility and precision of CNC machining. Here are some applications and features of CNC machining stainless steel:

Application:

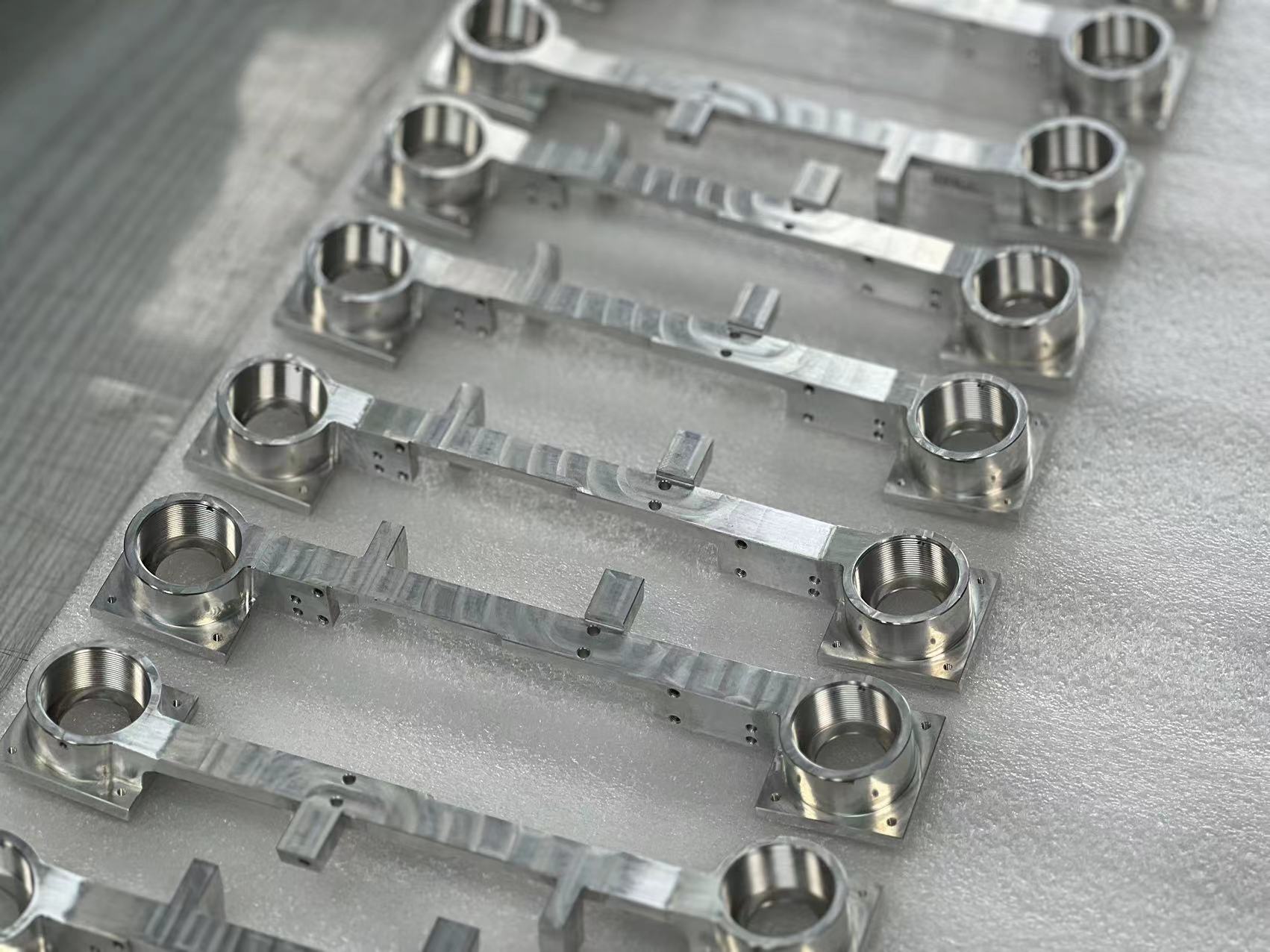

Parts manufacturing: CNC machining can be used to manufacture a variety of stainless steel parts, including mechanical parts, automotive parts, aerospace parts, etc. These parts may have complex geometries and strict dimensional requirements.

Mold Manufacturing: Stainless steel is often used to make molds, such as injection molds, die-casting molds, pressing molds, etc. CNC machining can accurately cut and process stainless steel materials to create high-quality molds.

Retail Products: Stainless steel is commonly used to manufacture a variety of retail products such as kitchen appliances, home decorations, jewelry, etc. CNC machining can achieve precise processing of stainless steel materials and produce products with beautiful appearance and reliable quality.

Medical Equipment: Stainless steel has good corrosion resistance and biocompatibility and is often used in the manufacture of medical equipment and instruments, such as surgical tools, implants, etc. CNC machining enables precision machining of stainless steel materials to meet the strict requirements of medical equipment.

Features:

Corrosion resistance: Stainless steel has good corrosion resistance and is suitable for applications in various harsh environments, such as seawater environment, chemical industry, etc.

High hardness: Stainless steel has a high hardness, so it needs to be processed with appropriate tools and processing parameters.

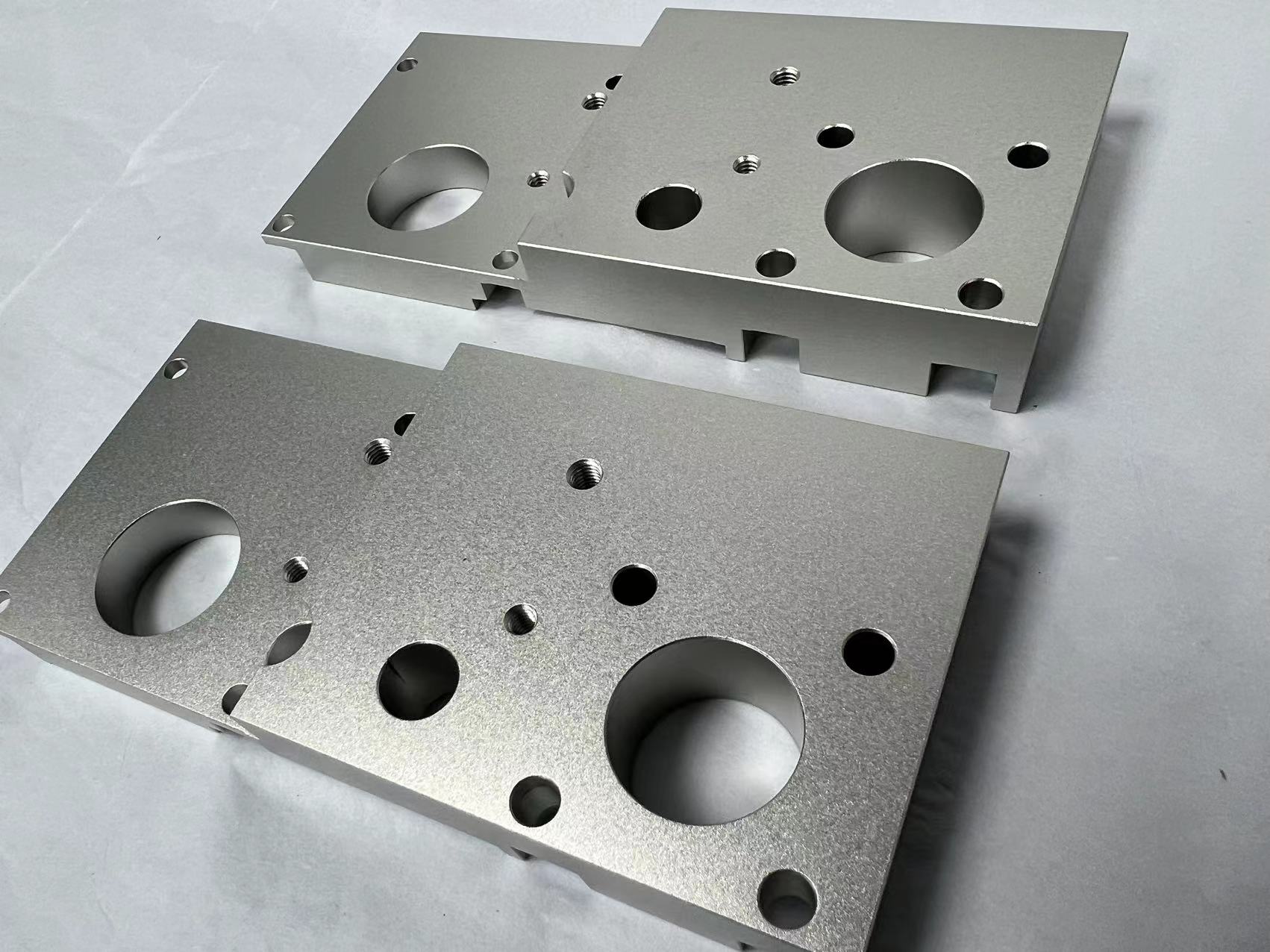

High machining precision: CNC machining has high precision and repeatability, and can achieve precision machining of stainless steel materials to meet various engineering requirements.

Good surface quality: CNC machining can achieve precision machining and polishing of stainless steel surfaces, creating smooth and uniform surface quality.

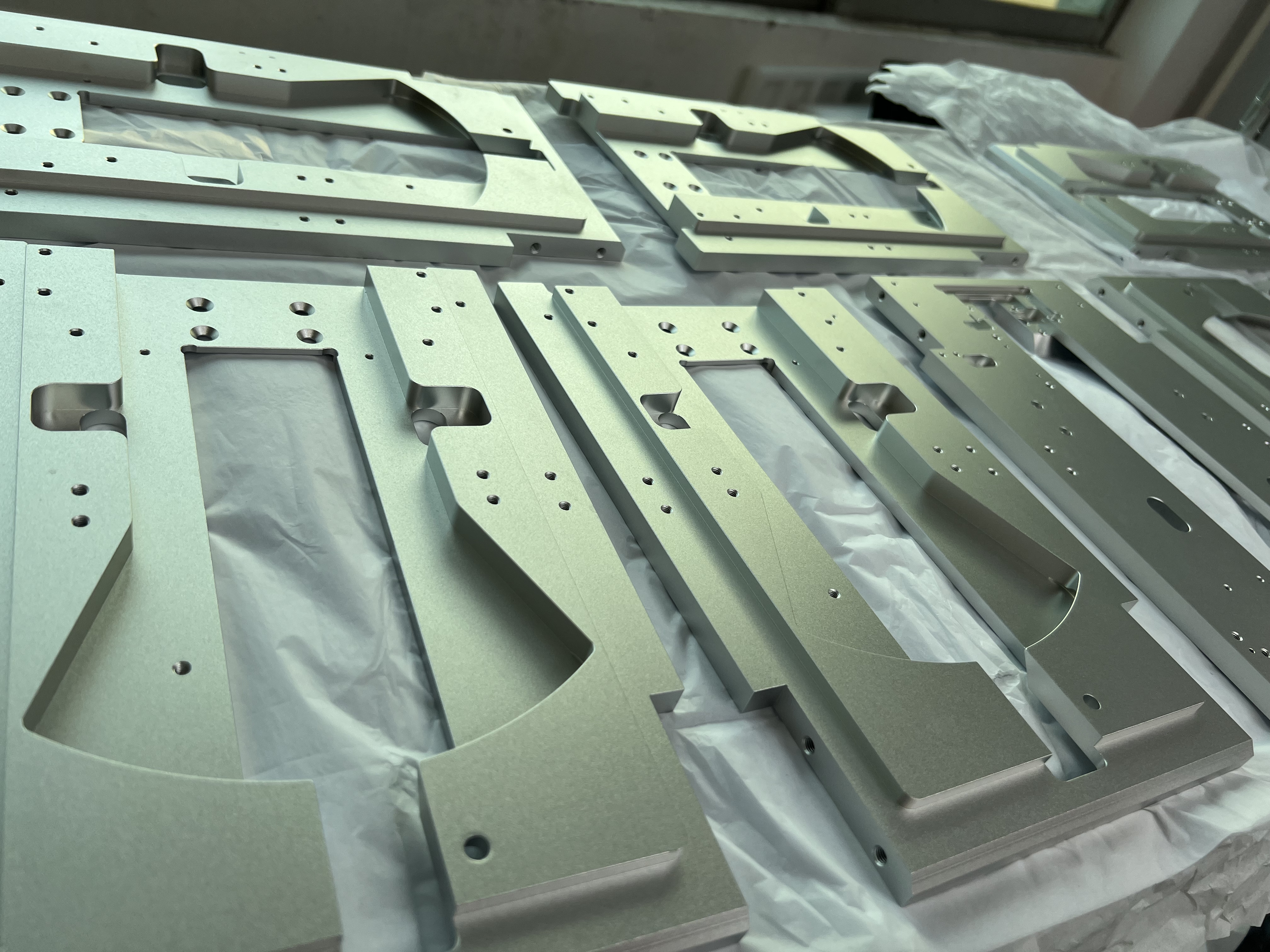

High flexibility: CNC processing has high flexibility and can be customized according to customer needs. It is suitable for the production of various stainless steel parts and products.

To sum up, CNC machining has a wide range of applications in stainless steel materials. It has the advantages of high precision, high efficiency and flexibility, and provides strong support for the development of stainless steel manufacturing industry.

Due to its corrosion resistance, high temperature resistance and high strength, stainless steel is often used to manufacture equipment or machines that require long-term stable operation and withstand harsh environments.