Perforated metal

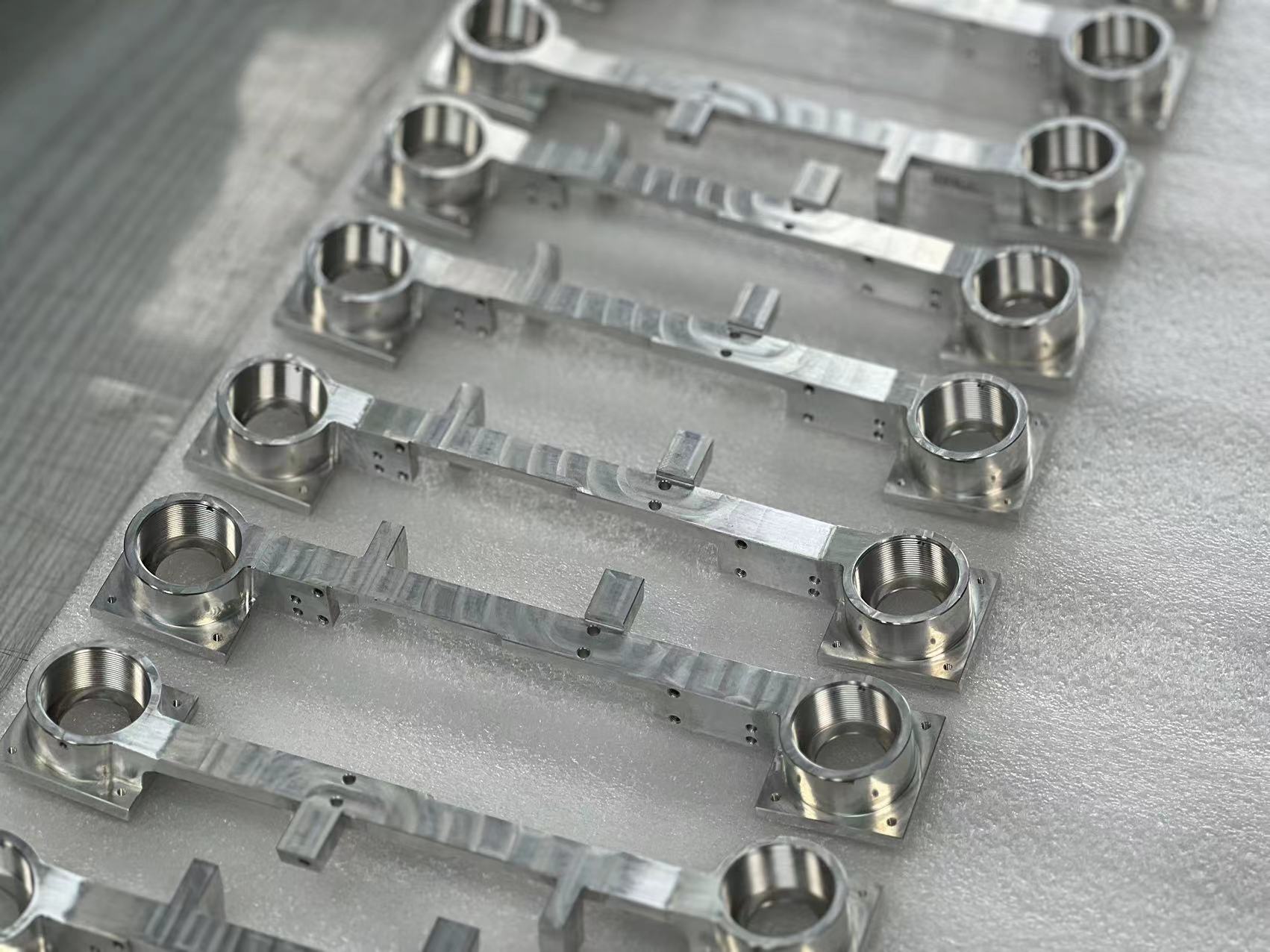

CNC Titanium Alloy Drilling Medical parts OEM

Material: TA1 Titanium Alloys

Process: CNC machining

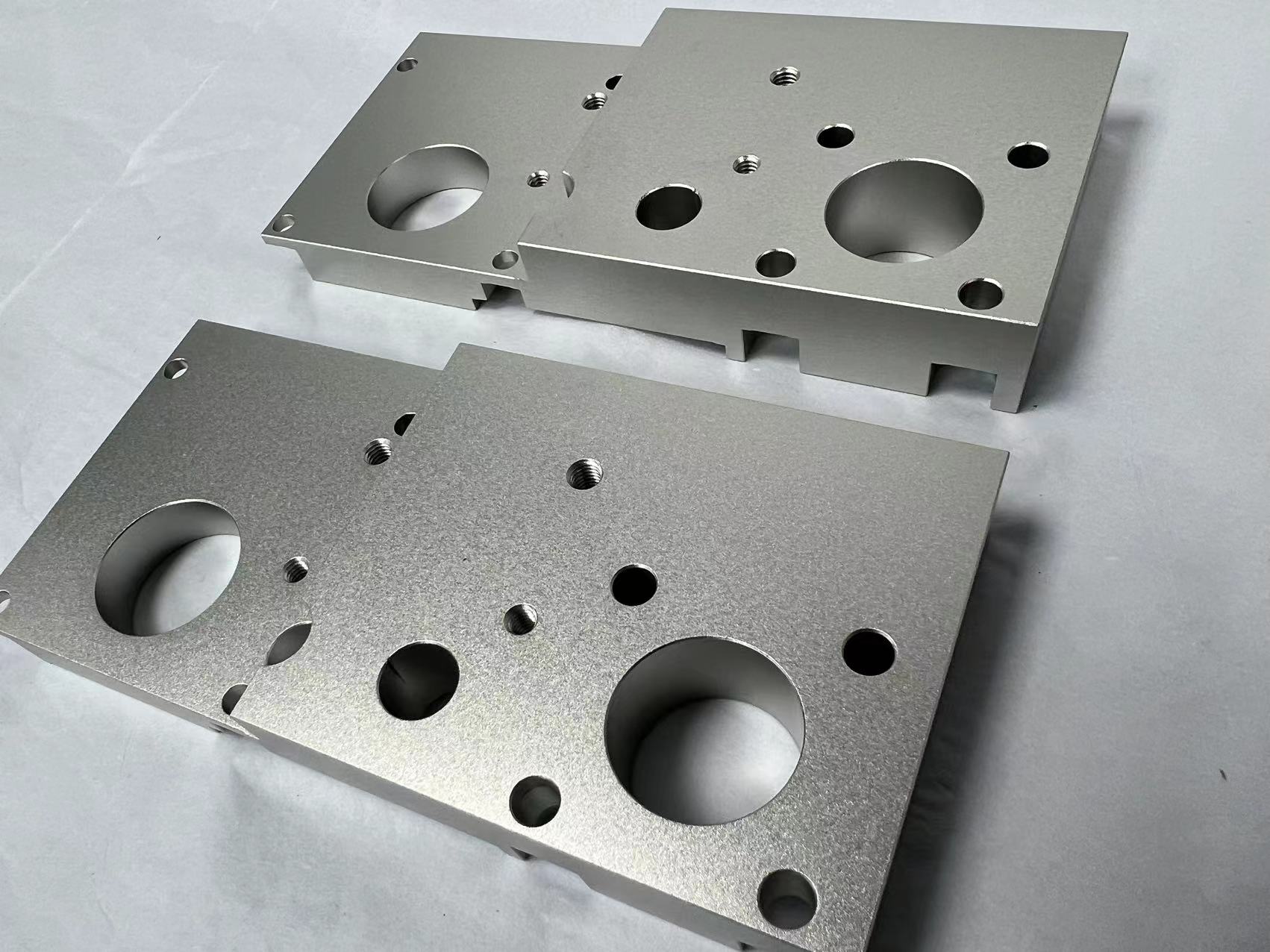

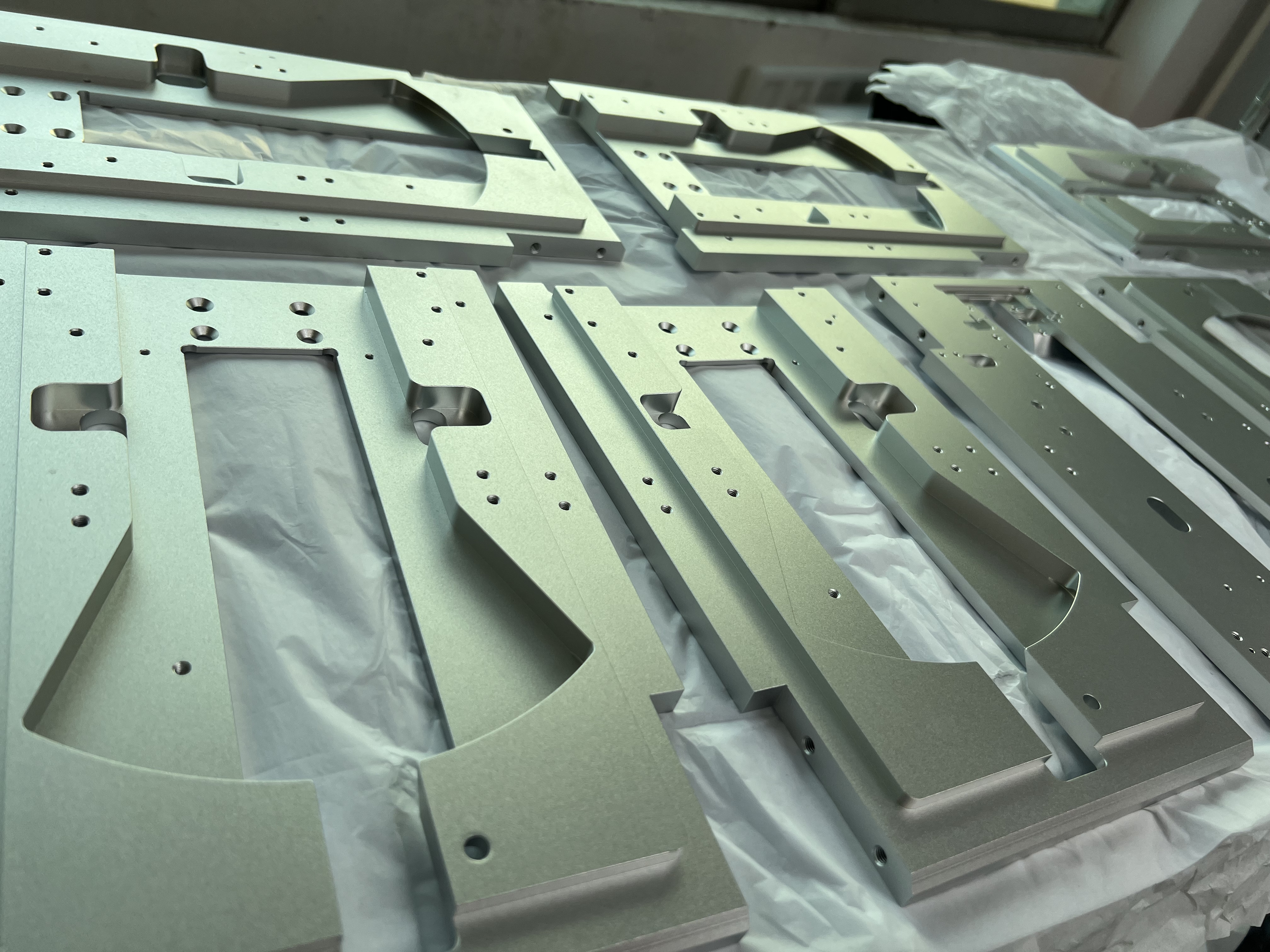

Finish: Anodizing

Quantity: 500

Lead Time: 2 weeks

Drawing:2D(CAD, PDF), 3D(STP, STEP)

Product Parts Category: Precision CNC Drilling Aerospace Parts

Machining Operations: CNC drilling is used to shape the brass stock into aerospace components. High-precision CNC machines with 3-axis capabilities are employed to achieve complex geometries and tight tolerances.

Quality Control: Throughout the machining process, quality control measures are implemented to verify dimensional accuracy and surface finish. Advanced metrology equipment such as coordinate measuring machines and optical comparators are used for precise inspection.

Surface Treatment: Depending on the specific requirements, brass aerospace parts may undergo surface treatments such as anodizing, plating, or passivation for improved corrosion resistance and durability. Surface finishes are carefully controlled to meet aerospace standards.

Final Inspection: Finished parts undergo rigorous final inspection to ensure they meet all specifications and quality standards. Any non-conforming parts are identified and either reworked or rejected.

Certification and Documentation: Material certifications, inspection reports are provided as necessary.

Packaging and Shipping: Finished aerospace parts are carefully packaged to prevent damage during transit and to maintain their integrity.