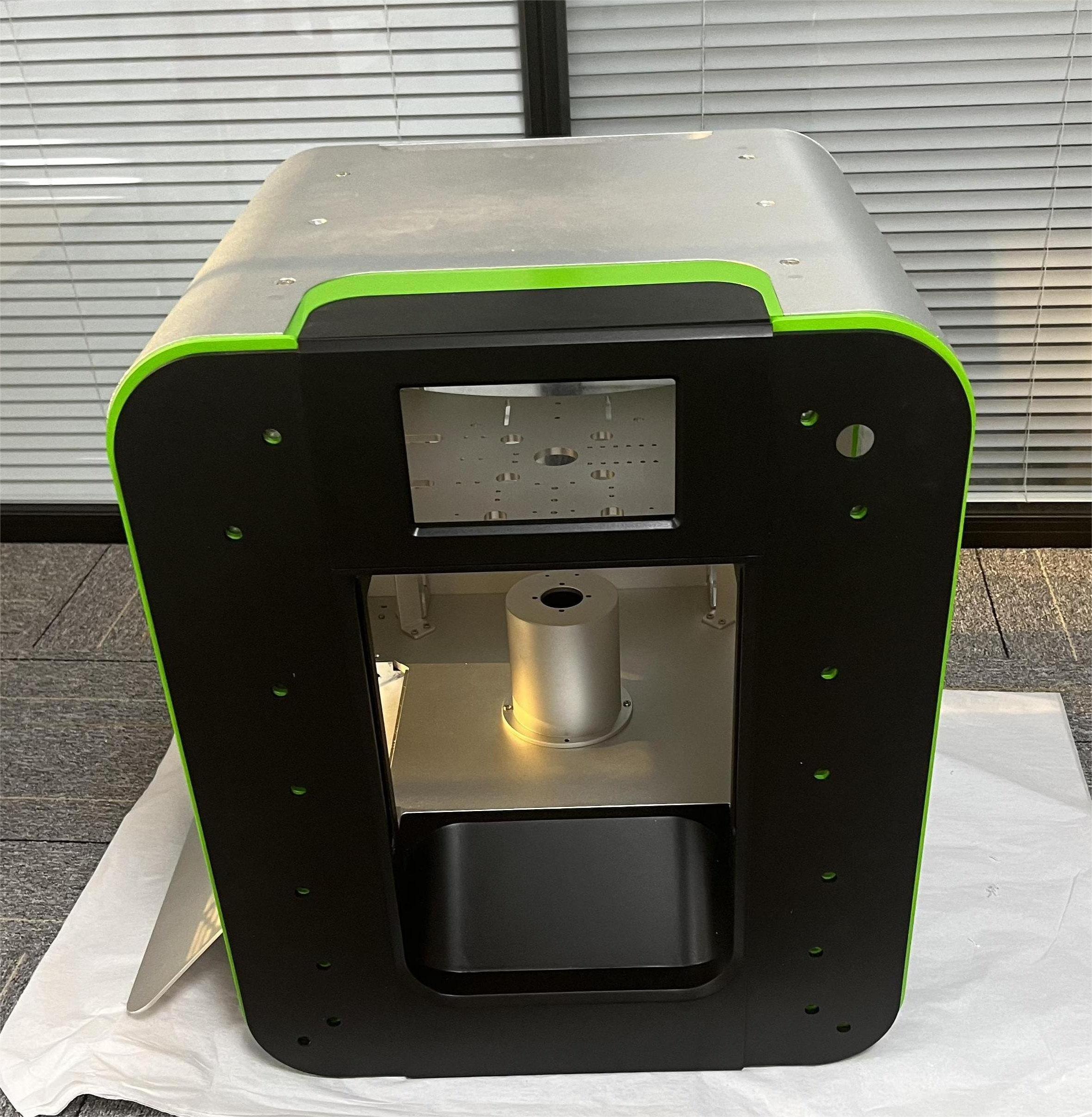

Medical Prototype

Medical Device Protoype Sheet metal Fabrication Aluminum Prototype

Material: Aluminum Alloy

Process: Five processes of sheet metal, riveting, welding, bending and stamping are completed together.

Finish: Spray paint

Sheet Matal Tolerance: ±0.05mm

Production time: 7 working day.

Drawing: 2D drawings (PDF/CAD) 3D drawings (STP, STEP)

Ruiyi's process for making aluminum alloy parts involves the following steps:

First, analyze the shape, size and tolerance requirements of the parts based on the drawings and models provided by the customer. After that, select the corresponding material according to the customer's requirements. (If you need other materials, please consult us. We provide 100+ metal and plastic material options, and you will find one you like.)

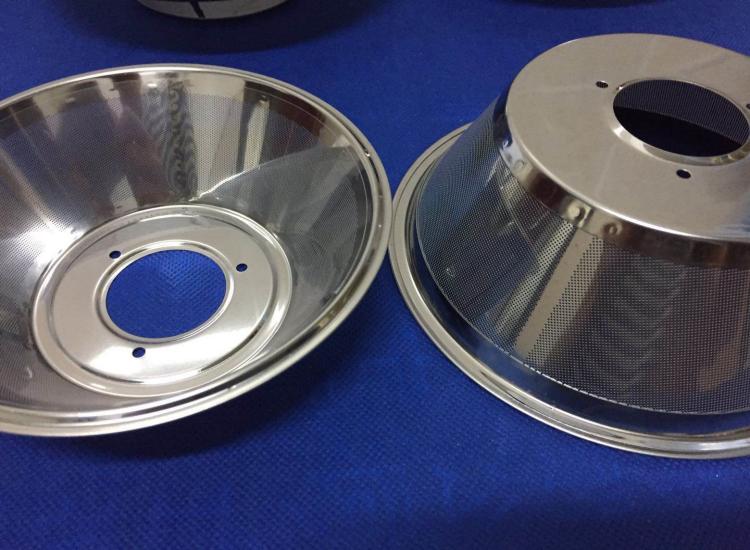

Next, use cutting and forming equipment, such as shears, laser cutting machines or plasma cutting machines, to cut and bend the aluminum alloy sheets into parts of the required size and shape.

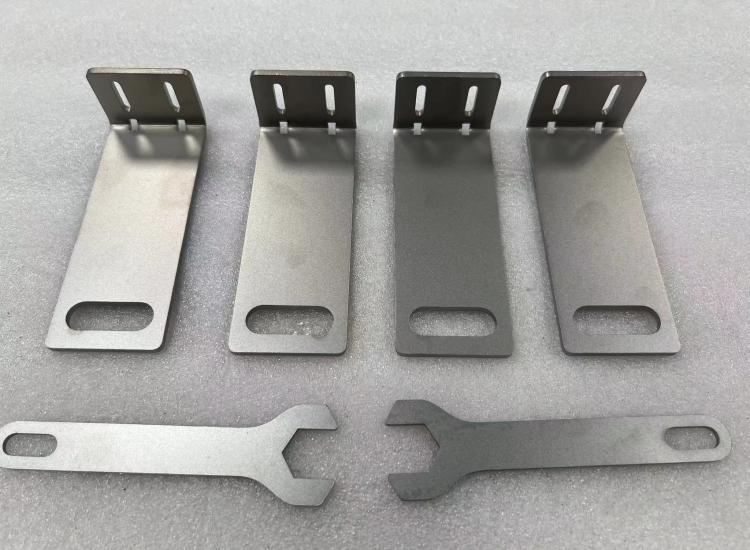

It is then assembled using welding techniques or connections such as bolts, nuts or rivets.

Finally, surface treatment is carried out according to customer requirements. In this case, we performed spraying, anodizing, sandblasting, polishing and other surface treatments on different parts.

During the production process, it is also necessary to constantly check whether each component is produced according to the requirements to meet customer expectations. After the processing is completed, professional testing will be conducted using two-dimensional testing equipment, micrometers, plug gauges, tooth gauges and other equipment. And form a test report to provide to customers.