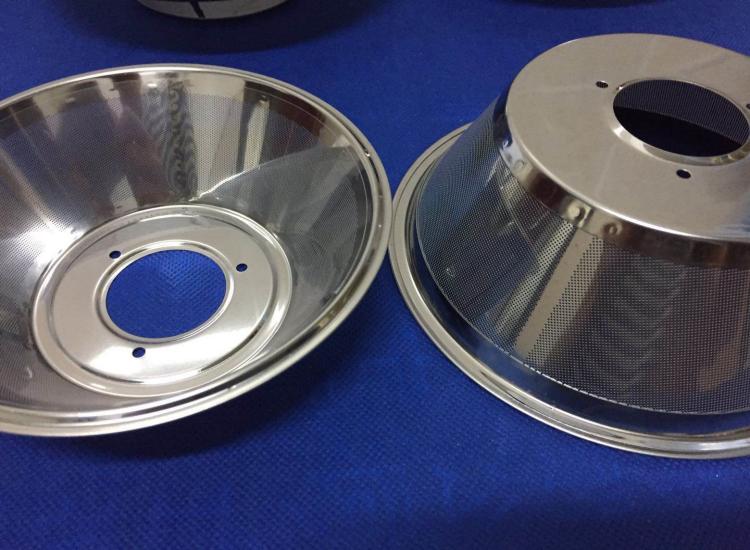

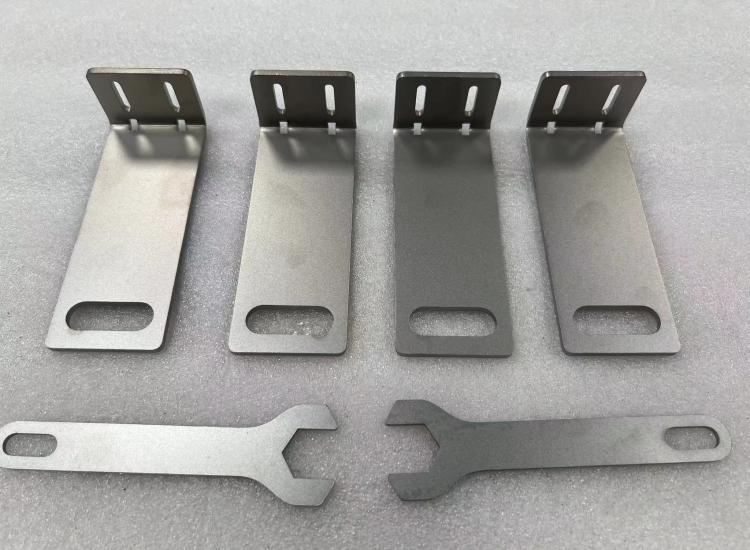

Laser cutting

Laser cutting principle: When a focused laser beam shines on the workpiece, the irradiated area will heat up rapidly to melt or vaporize the material. As soon as the laser beam penetrates the workpiece, the cutting process begins: the laser beam moves along the contours, melting the material at the same time. A jet of air is usually used to blow the melt away from the cut, leaving a narrow gap between the cut section and the platen that is nearly as wide as the focused laser beam.

Material: Mild steel is carbon steel with a carbon content of less than 0.25%. It is also called mild steel because of its low strength and hardness. It includes most ordinary carbon structural steel and some high-quality carbon steel. Most of them are used in engineering structural parts without heat treatment. Some are used in wear-resistant mechanical parts after heat treatment such as carburizing and nitriding.

Bending: ensure bending strength

Sheet metal bending needs to ensure bending strength. Long and narrow bending strength is low, and short and wide bending strength is high. Therefore, sheet metal bending should be attached to the longer edge as much as possible.

Press riveting: Press the preset holes in the sheet metal through embossed teeth. Generally speaking, the aperture of the preset holes is slightly smaller than the embossed teeth of the rivet nut. The teeth of the rivet nut are squeezed into the plate through pressure, causing the Plastic deformation occurs around the hole, and the deformed object is squeezed into the guide groove, thereby producing a locking effect.

Welding: Low carbon steel can be welded by almost all welding methods, and the welding quality can be guaranteed, such as: electrode arc welding, submerged arc welding, argon arc welding, secondary welding, flux cored wire gas shielded welding, electroslag welding, plasma Arc welding, laser welding, resistance welding, friction welding, brazing, gas welding, etc.

Post-processing: grinding and polishing to make the surface smooth and burr-free.

Packing: Use bubble cotton to wrap the parts, and finally transport them to the customer's country in wooden boxes.

If you are interested in sheet metal technology, contact us for details!