wheelchair accessories

The surface of the electroplating frame is hot-dip galvanized, which can be used to improve the corrosion resistance, aesthetics and wear resistance of metal products. The following is the production process of electroplated wheelchair frame:

1. Material preparation:

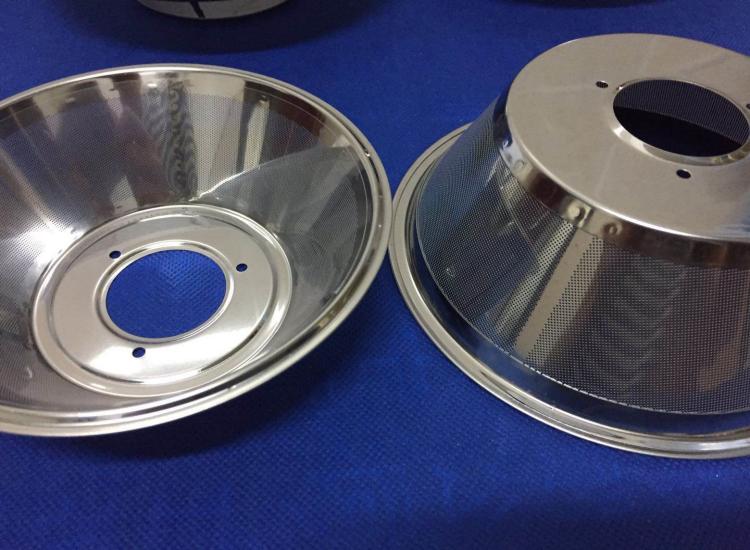

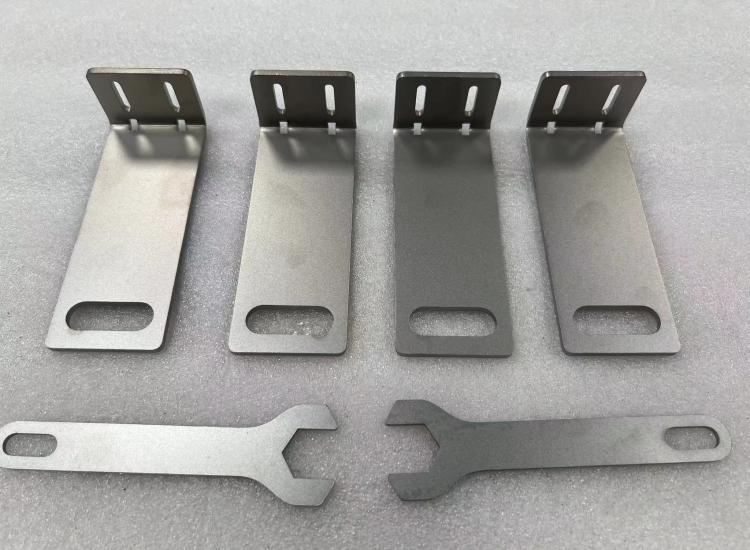

Choose high-quality metal materials, such as stainless steel or aluminum alloy, as the base material of the wheelchair frame.

Metal materials are cut, shaped and welded to create the basic shape of the wheelchair frame.

2. Surface treatment:

Before electroplating, the surface of the wheelchair frame needs to be pretreated to ensure the adhesion and uniformity of the electroplating layer.

Surface treatment includes cleaning, degreasing, removing oxide layers and other steps, usually using chemical cleaning or mechanical polishing.

3. Electroplating operation:

The pretreated wheelchair frame is placed in a plating bath and serves as the cathode, immersed in the electrolyte along with the anode (usually metallic nickel or chromium). By applying current and controlling the plating time, metal ions on the metal anode are deposited onto the surface of the wheelchair frame to form a uniform plating layer.

4. Electroplating layer treatment:

After plating is completed, the wheelchair frame is removed from the plating tank and cleaned and neutralized to remove residual electrolyte and chemicals. Polish or brighten the surface of the electroplated layer to enhance its luster and appearance.

5. Quality control:

Conduct quality inspection on the electroplated wheelchair frame, including appearance inspection, thickness measurement and corrosion resistance test. Ensure that the thickness, uniformity and adhesion of the plating layer meet standard requirements.

6. Assembly and packaging:

Assemble the electroplated wheelchair frame with other components to form a finished wheelchair.

Final inspection of the finished wheelchair, including functional testing and visual inspection.

The finished wheelchair is packaged to ensure safety and protection during transportation.

Through the above steps, an electroplated wheelchair frame with corrosion resistance and beautiful appearance can be produced. Electroplating technology can not only improve the appearance quality of metal products, but also increase their service life and performance.