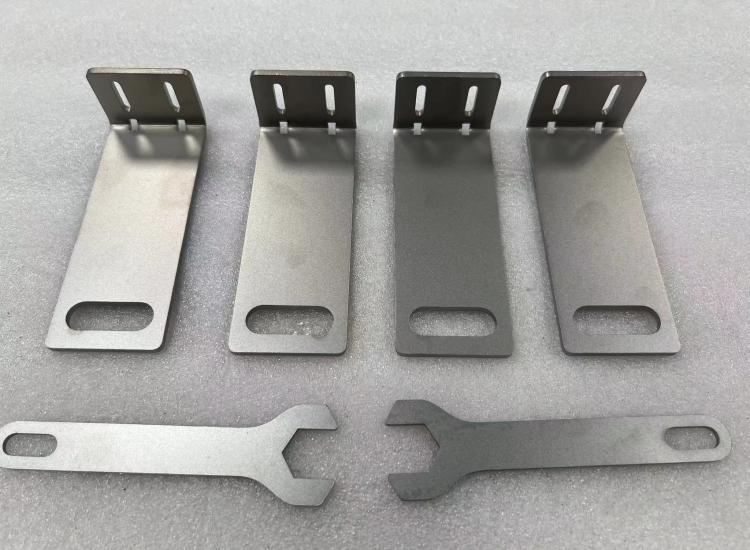

stainless steel sheet metal

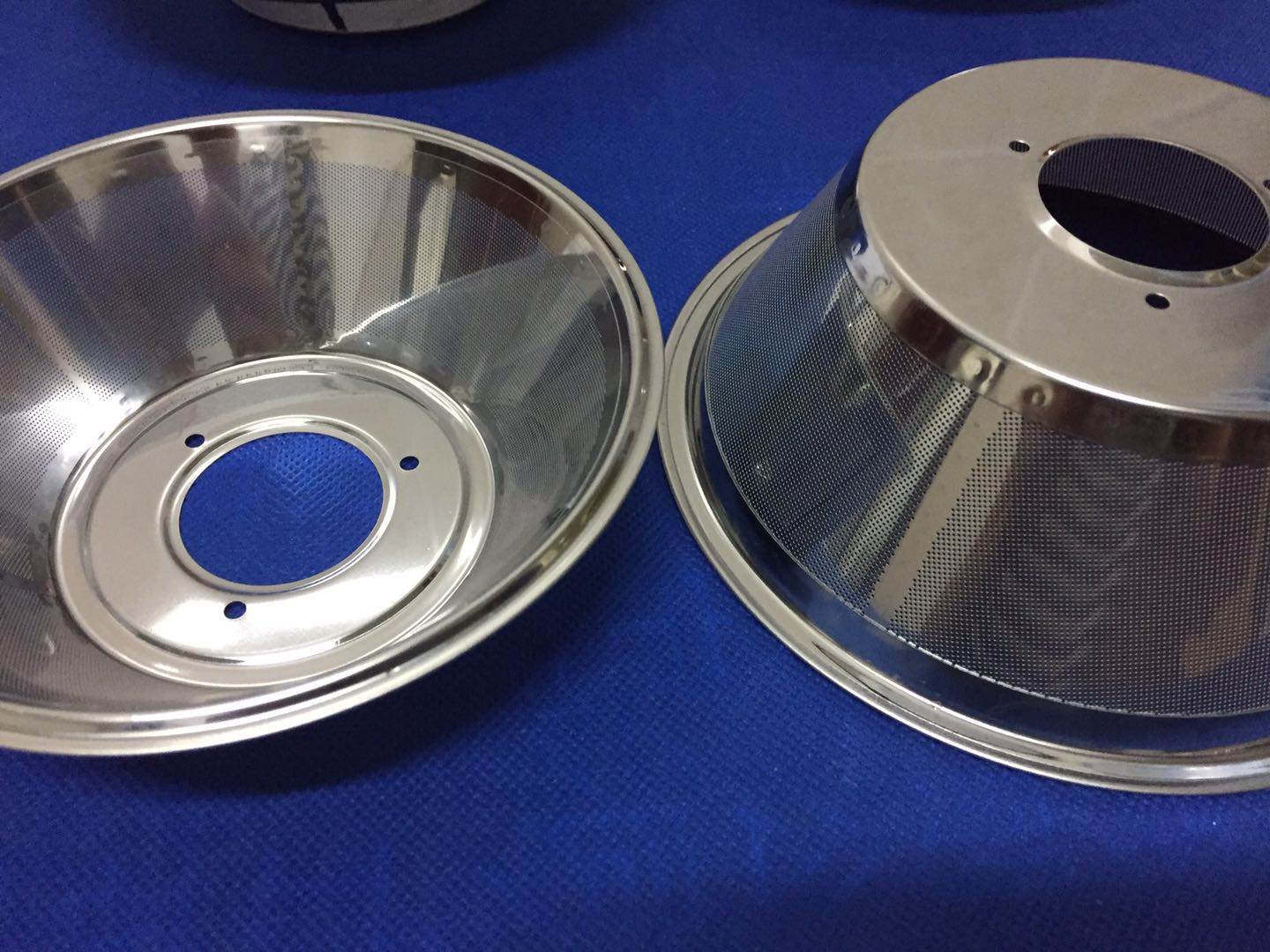

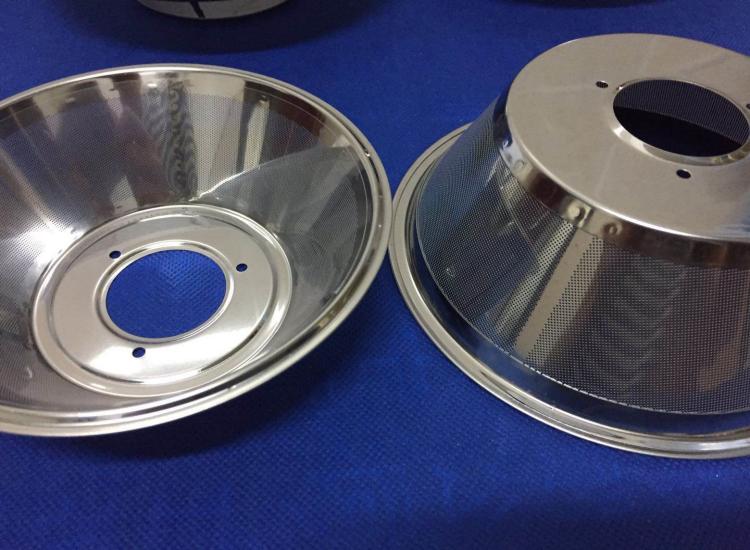

Sheet metal stainless steel Filter prototype

Material: Stainless Steel

Finish: Passivation

Production time: 5 working days

Drawings: pdf/ cad/ step/ stp

MOQ: 1, the more, the cheaper

Application: medical equipment, aerospace, auto parts, industrial equipment, etc.

Stainless steel sheet metal processing refers to the shearing, folding, and grooving of stainless steel and other metal sheets. Stainless steel sheet metal parts must be surface treated after folding, riveting and other processing steps.

The materials are different and the surface treatment methods are also different. Usually, the surface plating process is required after the cold plate is processed, and there is no need to carry out painting process after the plating process. The rest of the processing is usually vulcanized and then painted. Electroplating process boards must first carry out surface cleaning, degreasing, painting and other steps.

When folding stainless steel plates, the milling cutter and slot used for folding should be determined according to the material and specifications of the drawing standards. In order to avoid deformation, the selection of lower mold is the key. The selection of the lower mold depends on the thickness of the material.

In order to ensure firmness during welding, protruding points should be made on the product. The protruding points should evenly contact the material before plug-in welding to ensure that each soldering point is heated equally.