sheet metal prototyping

Sheet metal housing is commonly used in a variety of equipment, machinery, and electronic products to wrap and protect internal parts, components, or circuit boards. It can be a simple box structure or a housing with complex shape and structure. The following is the general manufacturing process:

1.Design: Design a suitable shell structure according to the function and requirements of the product. Factors such as the shape, size, wall thickness, connection methods, ventilation holes, etc. of the enclosure need to be taken into consideration during the design phase.

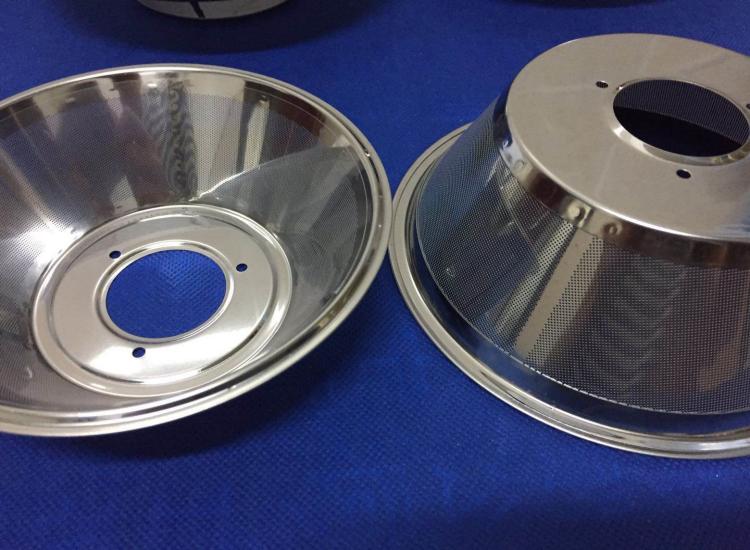

2.Material selection: Select suitable metal materials according to the product's use and environmental requirements. Common materials include steel plates, aluminum plates, stainless steel, etc. The choice of material will affect the strength, corrosion resistance, weight and other characteristics of the shell.

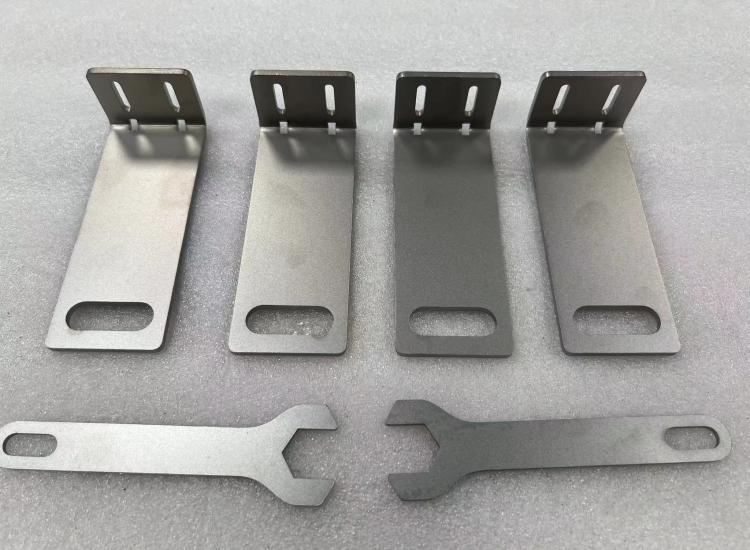

3.CNC cutting: Use CNC cutting equipment (such as laser cutting machine, plasma cutting machine) to cut metal sheets into parts of the required shape and size according to the design drawings.

4.Bending: Use a bending machine to bend the cut metal sheet to make it the basic structure of the shell. Bending molding usually requires precise control of the bending angle and bending position according to design requirements.

5.Welding: Connect the bent parts through the welding process to form a complete shell structure. Welding usually includes spot welding, gas shielded welding and other methods.

6. Surface treatment: According to the requirements of the product, the shell is surface treated, such as spraying, electroplating, anodizing, etc., to improve the appearance quality, corrosion resistance and wear resistance.

7.Assembly: Assemble the finished shell with other parts to form a complete product. The assembly process may involve bolting, riveting, gluing and other processes.

Quality inspection: Carry out quality inspection on the finished shell to ensure that the size, appearance and function of the shell meet the design requirements and standards.