What is vacuum injection molding? What types of products are suitable for production?

There are many ways to produce plastic products, and vacuum injection molding is one of them.

Vacuum injection molding (also called vacuum molding) is a specific method of producing plastic products. The specific process is: first, use 3D printing, CNC processing and other methods to create a prototype; then, use the prototype to make a silicone mold or A rubber mold (currently mainly silicone); then, under vacuum, liquid resin is injected into the mold and allowed to harden.

The general process of vacuum injection molding is as follows:1. Mold preparation

Design and build molds, which usually consist of two or more parts so that they can be closed after the resin is injected.

Lay reinforcement materials (such as carbon fiber cloth, glass fiber cloth, etc.) on the surface of the mold. These reinforcement materials will form the structural skeleton of the final product.

2.Material preparation

Prepare liquid resin (such as epoxy resin, polyester resin, etc.) to ensure the quality and applicability of the resin.

Prepare all necessary auxiliary materials, such as release agent, curing agent, etc.

3. Mold release agent:

Coat a release agent on the inner surface of the mold to facilitate the release of the cured composite parts from the mold.

4. Lay reinforcement materials:

Lay reinforcement materials in the mold according to the predetermined number of layers and directions.

According to product requirements, different types or thicknesses of reinforcement materials can be laid in different locations.

5. Install vacuum bag and seal:

Cover a layer of vacuum bag film on the laid reinforcement material.

Use sealing strips or tape to seal the vacuum bag film and the edge of the mold to ensure there is no leakage when injecting resin.

6. Set up the vacuum system:

Connect the vacuum pump and vacuum bag film to ensure that a stable vacuum environment can be maintained inside the mold when resin is injected.

7. Resin injection:

Open the resin injection port and inject liquid resin into the mold.

Under the action of vacuum, the resin will evenly penetrate between the reinforced materials and expel the air and excess resin.

8. Resin curing:

The resin solidifies in the mold, which can be achieved by heating, increasing pressure, or adding a curing agent.

The curing process takes a certain amount of time, and the specific time depends on the type of resin and curing conditions.

9. Demolding and trimming:

When the resin is completely cured, open the mold and remove the composite parts from the mold.

Perform necessary trimming and polishing of the protruded parts to meet the requirements of the final product.

10. Post-processing and detection:

Perform post-processing on components as needed, such as cutting, drilling, painting, etc.

Conduct quality inspection on components to ensure they meet design requirements and usage standards.

Advantages and Disadvantages of Vacuum Injection Molding

(advantage)

1. The vacuum injection molding machine is an intelligent device with a simple and clear operation interface. All operations can be completed automatically by simply setting the relevant parameters.

2. The vacuum injection molding machine can mold multiple parts at one time, greatly improving production efficiency. While reducing production costs, it can also increase production output to meet the needs of mass production.

3. Vacuum forming can control the shape and size of the product by adjusting parameters such as the molding mold, temperature, and pressure. The product has high dimensional accuracy and good repeatability.

4. During the molding process of vacuum forming, thermoplastic plastic is often attached to the surface of the mold, so the surface of the product is smooth and has no obvious gaps or marks.

5. The vacuum forming method is suitable for various types of thermoplastics, and can make plastic products of various shapes, sizes and uses, such as packaging boxes, plastic trays, plastic tableware, etc.

(shortcoming)

1. Silicone molds can generally only be used about 20 times.

2. Although the accuracy of vacuum injection molding is higher, it is still slightly lower than methods such as CNC processing and injection molding.

3. The materials that can be used for vacuum injection molding are relatively limited and are mainly suitable for thermoplastic plastics.

4. Due to the generation of volatile gases or uneven cooling when the wall thickness of the product is large, bubbles may appear inside the product.

5. When the injection pressure is too high or the mold fit accuracy is poor, the plastic melt may be extruded from the parting surface into the mold cavity, forming flash or burrs.

Vacuum injection molding has the characteristics of high molding precision, good surface flatness, and strong adaptability. Therefore, it is suitable for producing many types of products, including but not limited to:

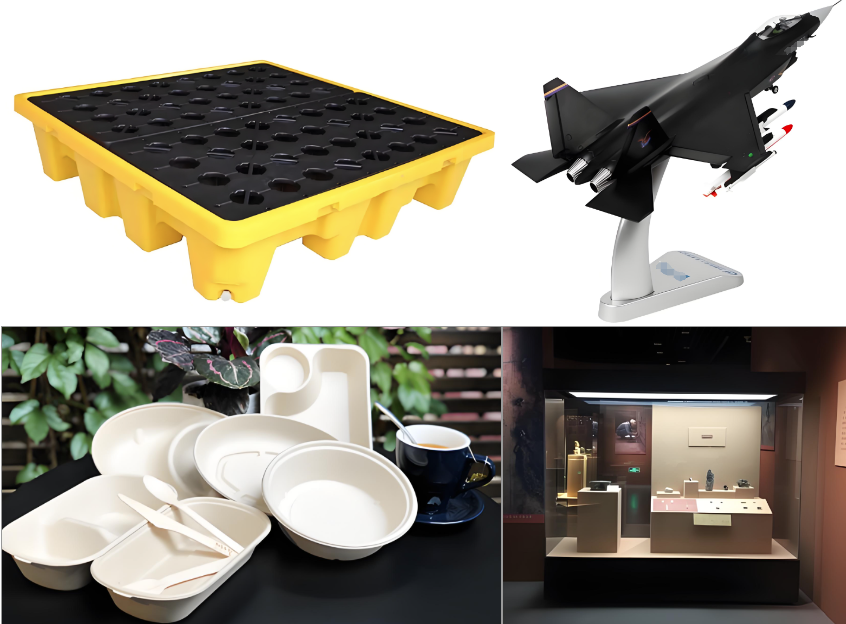

1. Packaging boxes: Vacuum injection molding can produce various types of plastic packaging boxes such as disposable plastic tableware and beverage cups.

1. Packaging boxes: Vacuum injection molding can produce various types of plastic packaging boxes such as disposable plastic tableware and beverage cups.

2. Plastic pallets: This method can make plastic pallets such as disposable plastic pallets and conference stacking trays. These pallets are usually used to carry, transport and store items and have the characteristics of strong durability and light weight.

3. Plastic tableware: Vacuum injection molding can make various types of plastic tableware, such as plastic bowls, plates, cups, etc. These products can be reused and are easy to clean and disinfect.

4. Toy models: such as car models, airplane models, animal models, etc. Vacuum forming method can produce a variety of toy models.

5. Display rack: Display racks widely used in shopping malls, supermarkets, museums and other places can also be produced by vacuum injection molding. The shape design is determined by the mold produced.

(In general, the vacuum injection molding method is suitable for making plastic products of various shapes, sizes and uses.)