Common methods for machining custom housings

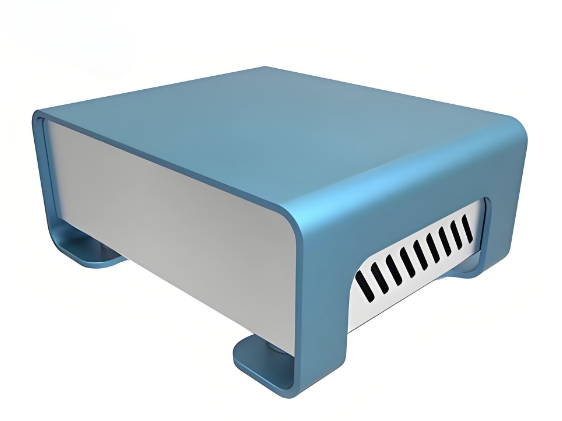

Custom enclosures serve different purposes in different industries. They are used to protect and contain electronic components, electrical equipment or equipment in a variety of applications. Manufacturers commonly use custom electronic enclosures in a variety of applications including consumer electronics, medical devices, automotive electronics, industrial control systems, and more. These custom mechanical enclosures protect these devices from environmental, electromagnetic, and radio frequency interference.

Manufacturers often use machined casings to enhance the cosmetic appeal of their products and ensure they are suitable for their intended use. Additionally, these enclosures facilitate optimal customization, allowing designers to meet specific product design requirements and dimensions for efficient component assembly.

Additionally, custom cases are great for protecting electronic components and equipment, ensuring safety. They also protect against contaminants such as chemicals, dust, moisture and physical hazards, reducing the risk of electrical shock.

Different methods of custom enclosure manufacturing

Product engineers and designers employ custom enclosure manufacturing methods that meet specific requirements. However, the ideal approach depends on design complexity, materials used, budget considerations, and prototype-to-production quantities.

Common methods for machining custom casings mainly include the following:

1. Cutting and Drilling:

Use equipment such as cutters, laser cutters, water jets, etc. to cut and drill the material to meet the dimensional requirements of the enclosure. This method is often used to manipulate raw materials into shapes and sizes that meet design requirements.

2. Bending and forming:

For metal materials, bending and forming may be required to obtain the desired shape and structure. This can be achieved through equipment such as bending machines and stamping machines.

3. Welding and assembly:

The cut, drilled, and bent parts are welded and assembled to form a complete shell. Welding methods include arc welding, laser welding, TIG welding, etc.

4. Sheet metal processing:

Sheet metal fabrication is a widely used processing method for custom machine housings. It involves using specialized machines to bend or form metal to produce custom electrical enclosures with the desired shape. This technique is suitable for making durable housings with precise dimensions and is often cheaper than CNC machining.

5.3D printing:

The 3D printing or additive manufacturing process creates custom electronic boxes by stacking them layer by layer and is suitable for creating test prototypes, custom designs and low-volume enclosures with complex geometries. This additive manufacturing technology offers greater speed and greater design freedom than most methods.

6. Vacuum or polyurethane casting:

Vacuum casting is an efficient method of manufacturing custom enclosures that is faster and more economical than injection molding. This technology can easily produce low-volume housings, making it ideal for manufacturing medical devices and full-scale robot housings.

Metal materials for custom enclosures

There are different materials available for custom enclosures for various applications, as long as you understand the requirements of the product. The metals best suited for housings typically have properties that resist wear and corrosion as they are exposed to specific operating conditions. This section discusses the different metal materials available for custom enclosures.

Aluminum

Aluminum is a lightweight and corrosion-resistant metal that has significantly lower stiffness levels compared to steel under certain conditions. Although aluminum comes in different grades, 5052 and 6061 aluminum are the primary aluminum alloys commonly used for custom enclosures.

Additionally, these aluminum alloys are ideal for custom aluminum enclosures due to their corrosion-resistant and lightweight properties. However, you may want to anodize aluminum parts to enhance their durability and physical properties, and chrome coatings are also available as an ideal alternative for parts that require electrical contact.

Stainless steel

Stainless steel includes nickel and chromium, which provide greater corrosion resistance. Additionally, stainless steel has higher tensile strength than aluminum. Therefore, this material is ideal for custom housing designs with high impact needs. Additionally, stainless steel parts provide a textured surface.

Galvanneal steel

This metal is a mild steel that has a zinc coating and is annealed. Annealing ensures that the zinc adheres by diffusion into the substrate. Therefore, the zinc coating will not peel off when bending or forming. Therefore, if your product needs to operate in humid conditions, Galvanneal is ideal for manufacturing mechanical enclosures. What's more, depending on its coating, Galvanneal is also corrosion-resistant.

CRCA

Coiled mild annealed steel material is ideal for indoor enclosures and components. CRCA provides an ideal combination of strength and stiffness for mechanical enclosures. Therefore, indoor applications ensure its maximum long-term durability. However, CRCA lacks inherent corrosion resistance and may rust if not coated.

In addition, depending on specific needs and material characteristics, other processing methods may also be used, such as injection molding, blow molding, extrusion molding and other plastic processing techniques. The choice of these process methods depends on the material of the housing, design complexity, production volume, and cost considerations.

It should be noted that machining customized casings is a complex process that requires the flexible application of different processing methods and technologies based on specific circumstances to meet customer requirements. At the same time, for high-precision and high-quality shell manufacturing, it is also necessary to strictly control various parameters and process conditions during the processing to ensure the performance and quality of the final product.