Take you to understand rapid prototyping in 1 minute

Rapid prototyping technology, also known as rapid prototype technology, is an important part of modern advanced manufacturing technology. Rapid prototyping equipment can directly, quickly and accurately transform design ideas or design plans into actual part prototypes or directly manufacture parts through processes such as model establishment, approximation processing and slicing processing, and provide prototype production and verification of design ideas for parts, etc. It provides an efficient and low-cost implementation method, which makes up for the shortcomings of traditional manufacturing methods.

Rapid prototyping technology is based on the principle of discrete/accumulation molding. According to the three-dimensional CAD model, the CAD model is layered according to a certain thickness, and the three-dimensional model is turned into a two-dimensional plane model with a very thin thickness. Then the two-dimensional model is processed for data, processing parameters are added, and each thin layer is continuously processed by plane processing under the control of the CNC system, and bonded to form it.

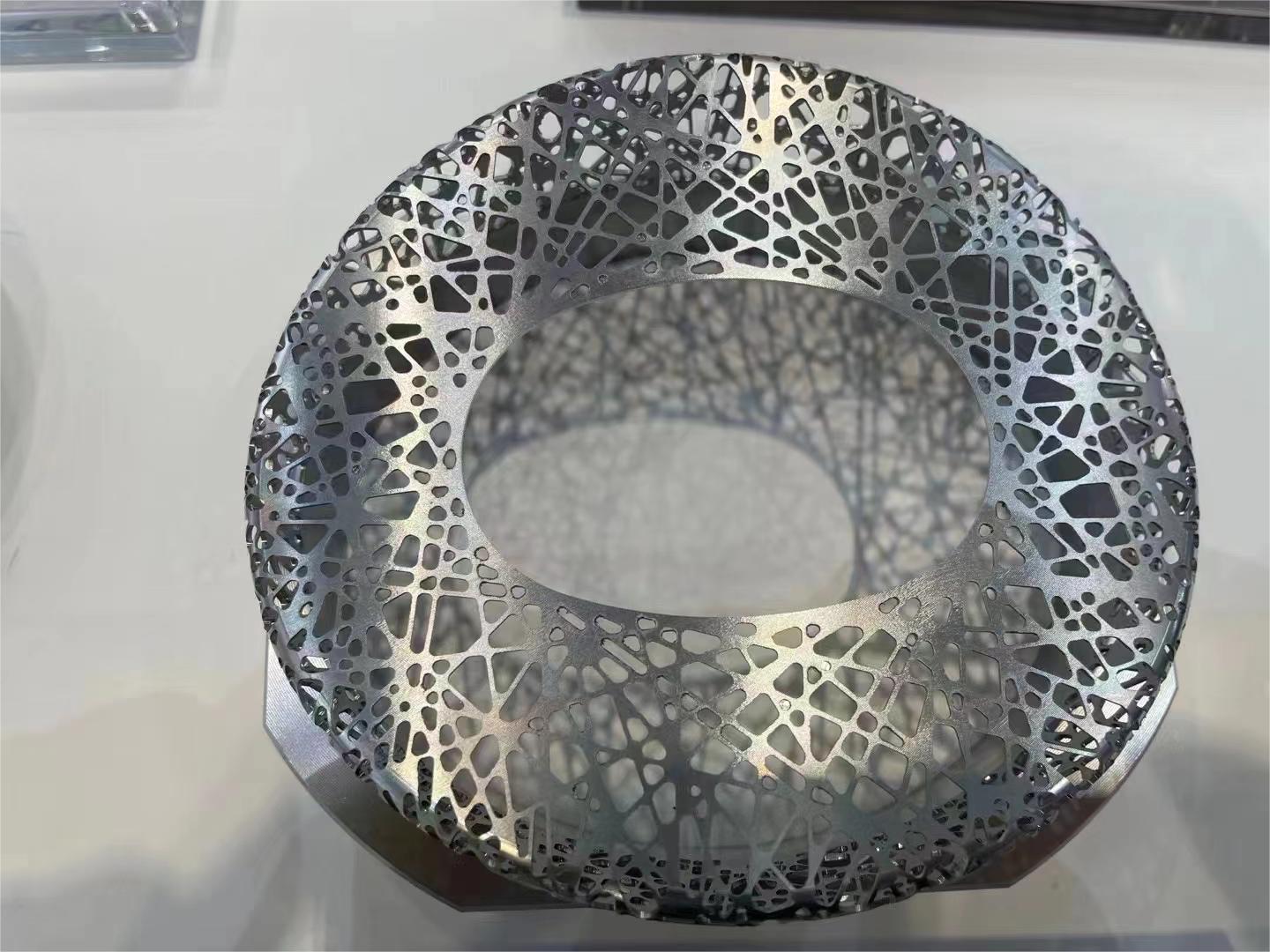

Ruiyi rapid prototyping has many process methods. All rapid prototyping methods manufacture parts layer by layer. The difference is that each method uses different materials and different bonding methods. Typical rapid prototyping technologies include stereolithography (SLA), fused deposition deposition (FDM), laser powder sintering (SLS) and stacked outline (LOM).

Compared with traditional processing methods, rapid prototyping technology has obvious advantages in speed, integration, applicability, adjustability and automation. For example: Rapid prototyping technology achieves completely automated molding. The operator only needs to input relevant parameters, and the entire process can be automated without excessive intervention.

In recent years, rapid prototyping technology has developed greatly. It covers a wide range of fields and has many application industries, mainly concentrated in industrial manufacturing, construction industry, medical field, artistic creation, archaeological research, aviation space and other fields.

With the development of rapid prototyping technology, it is widely used in the mold manufacturing process. This technology can carry out rapid trial production of new products, and the production cycle is only about 1/4 of traditional technology, which can effectively improve the first-time success rate of mold manufacturing. This technology integrates the conceptual design and production process of the mold in the CAD system, and uses computer simulation analysis to form a new mold design and manufacturing system. Complex curved surfaces and other structures can be manufactured without CNC cutting, which is beneficial to improving the quality of the mold. Manufacturing flexibility and quality.

In order to use rapid prototyping technology as a new advanced manufacturing technology more widely in various industries, we also need to invest a lot of research and development in basic theory, practical application and other aspects. In the future, rapid prototyping technology will promote the development of related technologies and industries.