What preparations should be made before CNC programming?

01. What preparations should be made before CNC programming?

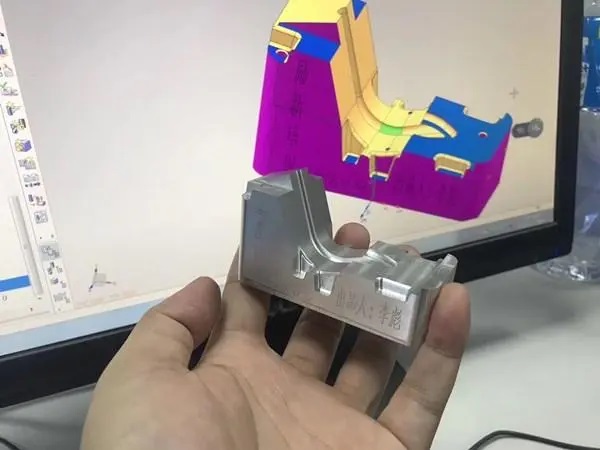

After determining the processing technology, you need to understand the following before programming:

1.1 Workpiece clamping method;

1.2 The size of the workpiece blank ---- in order to determine the scope of processing or whether multiple clamping is required;

2.3 The material of the workpiece----in order to choose which tool to use for processing;

3.4 What are the tools in stock? Avoid modifying the program due to the lack of this tool during processing. If this tool must be used, you can prepare it in advance.

02. What are the principles for setting the safety height in programming?

The setting principle of safe height: generally higher than the highest surface of the island. Or set the programming zero point on the highest surface to avoid the risk of tool collision to the greatest extent.

03. After the tool path is programmed, why does it need to be post-processed?

Because the address codes and NC program formats recognized by different machine tools are different, it is necessary to select the correct post-processing format for the machine tool used to ensure that the programmed program can run.

04.What is DNC communication?

Program transmission methods can be divided into two types: CNC and DNC. CNC means that the program is transported to the memory of the machine tool through media media (such as floppy disks, tape readers, communication lines, etc.) and stored. The program is called out from the memory during processing. processing. Since the memory capacity is limited by the size, DNC processing can be used when the program is large. Since the machine tool directly reads the program from the control computer during DNC processing (that is, it is sent and processed at the same time), it is not affected by the memory capacity. limited by size.

1) There are three major factors in cutting amount: cutting depth, spindle speed and feed speed. The general principle of selecting cutting amount is: less cutting, fast feed (that is, small cutting depth, fast feed speed)

2) According to material classification, knives are generally divided into ordinary hard white steel knives (the material is high-speed steel), coated knives (such as titanium plating, etc.), and alloy knives (such as tungsten steel, boron nitride knives, etc.).