What are the characteristics of common CNC plastic processing materials?

CNC processing is a commonly used plastic processing method, which mainly uses computer numerical control technology to control machine tools for processing operations. CNC processing of plastics has the advantages of high precision, high efficiency, and high flexibility, so it has been widely used in the field of plastic processing.

01.ABS plastic

ABS is a comprehensive general-purpose plastic. It offers high impact strength, toughness and resistance at an affordable price. It's also easy to finish, as it can be easily painted, glued, or welded together. If left as is, it will have a matte finish.

Advantages: ABS plastic is a common thermoplastic with good mechanical properties and processing properties. It can realize automated and continuous production, improve the processing efficiency of ABS plastic parts, or is the best choice when low cost is required.

Disadvantages: ABS does not have good abrasion or chemical resistance and will melt in acetone. It's also not a particularly strong plastic. In addition, heat is easily generated during processing, causing material deformation.

Applications: The most common application of ABS is injection molding, used to make electronic casings, home appliances, and even the iconic Lego bricks.

02.Nylon

Nylon is a strong and durable plastic with excellent resistance to abrasion, heat and chemicals, making it perform well in a variety of environments and usage scenarios. Suitable for many uses.

Advantages: Nylon has high strength and stiffness, holds up over a wide temperature range, has good electrical insulation, and has good chemical and abrasion resistance. Nylon is ideal for applications that require low-cost, strong and durable components and can replace traditional metal materials such as steel, iron, copper, etc. in some applications to achieve lightweighting, reduce costs and increase production efficiency.

Disadvantages: Nylon material is hygroscopic and easily absorbs moisture in the air. This may lead to dimensional changes during processing, affecting processing accuracy and part stability. Nylon may undergo thermal expansion due to heat during processing, causing part dimensions to change. Distortion can also occur if a large amount of asymmetric material is removed during processing due to inherent internal stresses in the material.

Applications: Nylon is most commonly found in medical devices, circuit board mounting hardware, automotive engine compartment components, and zippers. It is used as an economical replacement for metals in many applications.

03. PEEK

PEEK is a high-performance engineering plastic with excellent wear resistance and chemical resistance, and is suitable for various harsh environments and usage scenarios.

Advantages: PEEK material has excellent high temperature stability and can maintain its mechanical properties and dimensional stability under high temperature conditions. It can replace traditional metal materials in some applications to achieve lightweight, reduce costs and improve production efficiency.

Disadvantages: Heat is easily generated during processing, causing the material to soften and deform. The price of PEEK materials is higher, resulting in correspondingly higher processing costs.

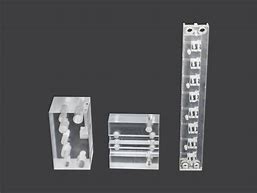

04.PMMA

PMMA is acrylic, also known as plexiglass. It is tough, has good impact strength and scratch resistance, and can be easily bonded using acrylic cement.

Advantages: It's ideal for any application that requires optical clarity or translucence, or as a less durable but less expensive alternative to polycarbonate.

Disadvantages: PMMA is a brittle plastic, which fails by cracking or shattering rather than stretching. Any surface treatment on a piece of acrylic will lose its transparency, giving it a frosted, translucent appearance. Therefore, it is generally best to pay attention to whether PMMA parts should remain stock thickness to maintain transparency. If the machined surface requires transparency, it can be polished as an additional post-processing step.

Applications: After processing, PMMA is transparent and is most commonly used as a lightweight replacement for glass or light pipes.

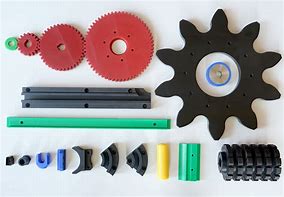

05.POM

POM is a special brand of acetal homopolymer that has a smooth, low friction surface, excellent dimensional stability and high stiffness.

Advantages: POM is a great plastic for these or any other applications that require a lot of friction, require tight tolerances, or require a high stiffness material.

Disadvantages: POM is difficult to glue. The material also has internal stresses that make it susceptible to warping in areas that are thin or have extensive asymmetric material removal.

Applications: POM is often used in gears, bearings, bushings and fasteners, or in the manufacture of assembly jigs and fixtures.

06.PC

PC is our most durable plastic.

Advantages: It has high impact resistance and stiffness, and remains functional over a wide temperature range. It is also optically clear and can be dyed black if required to be opaque. PC is best suited for applications that require very hard or very strong plastics, or where optical clarity is required. Therefore, PC is one of the most used and recycled plastics.

Disadvantages: Pure PC does not have good wear resistance and is easily scratched. If desired, scratch-resistant coatings and vapor polishing can be added as post-processing steps to improve wear resistance or optical clarity. It also doesn't have two-inch-thick parts readily available, which limits the size of PC parts.

Applications: PC's durability and transparency mean it can be used to make optical discs, safety glasses, light pipes and more.

07.PP

PP material has excellent tensile strength, compressive strength, wear resistance and fatigue resistance, and is suitable for manufacturing parts that need to withstand certain loads and wear.

Advantages: PP materials are less likely to generate heat during processing, reducing the problem of thermal deformation. PP materials show good stability to many chemical substances and can resist erosion by acids, alkalis, grease and other substances. Compared with other high-performance plastics, the price is relatively low and highly cost-effective.

Disadvantages: The temperature resistance of PP materials is relatively low, and long-term high-temperature use may cause material performance degradation or deformation. The surface hardness is relatively low, it is easy to be scratched or worn, and it is prone to shrinkage during processing. Corresponding compensation needs to be made during the design and processing process to ensure the dimensional accuracy of the parts.

Applications: PP materials are widely used in the manufacture of automobile fenders, interior parts, door seals and other components, shells, brackets and parts of various mechanical equipment, handles, brackets and connectors of medical equipment, etc.

08.HDPE

HDPE is high density polyethylene.

Advantages: HDPE is a very low-density plastic that also has excellent chemical resistance, electrical insulation and a smooth surface. It is ideal for making plugs and seals due to its chemical resistance and sliding properties, but is also a great choice for weight-sensitive or electrically sensitive applications.

Disadvantages: The main disadvantage of HDPE is its poor strength, especially in stretching and bending.

Applications: HDPE is commonly used in fluid applications such as fuel tanks, plastic bottles, and fluid flow tubes.

Shenzhen Ruiyi Model Technology Co., Ltd. offer CNC processing plastic service can also process many other plastic materials, such as PA, PTFE, etc. While CNC machining plastics offers many advantages, there are also some limitations and caveats. For example, some complex-shaped plastic parts may require multiple processes to complete; at the same time, different plastic materials have different processing properties and application ranges, and need to be selected according to the actual situation.