Rapid Prototype

Rapid prototyping is a method that uses rapid manufacturing technology to quickly produce product prototypes. This approach uses computer-aided design (CAD) data to create physical models for testing, evaluation, and validation early in the product development cycle.

Common rapid prototyping technologies include:

1. Sheet metal manufacturing: It is a manufacturing method that uses thin plate metal (usually steel, aluminum, stainless steel, etc.) to process and shape. This method involves cutting, bending, forming, welding and other processes of sheet metal to create a variety of metal parts, components and structures.

2. CNC processing: CNC processing can use CAD files to directly cut and process engineering materials (such as metal, plastic, wood, etc.) to quickly produce high-precision prototypes.

3. Rapid injection molding: This is a traditional method used to manufacture plastic parts, but by using rapid tool manufacturing technology, injection molds can be quickly made and small batches of plastic prototypes can be quickly produced.

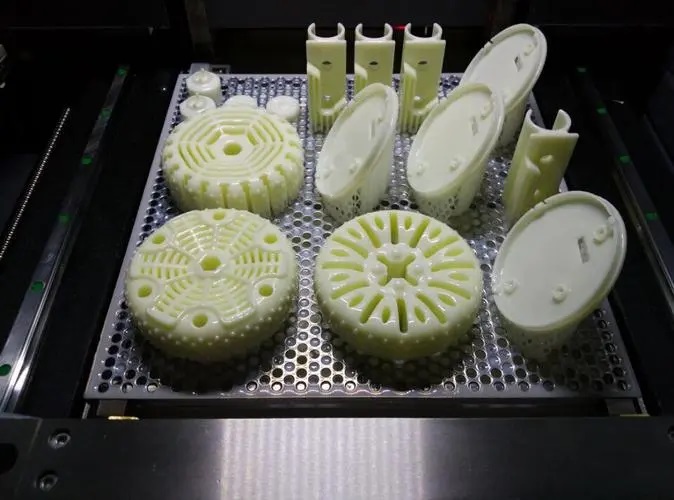

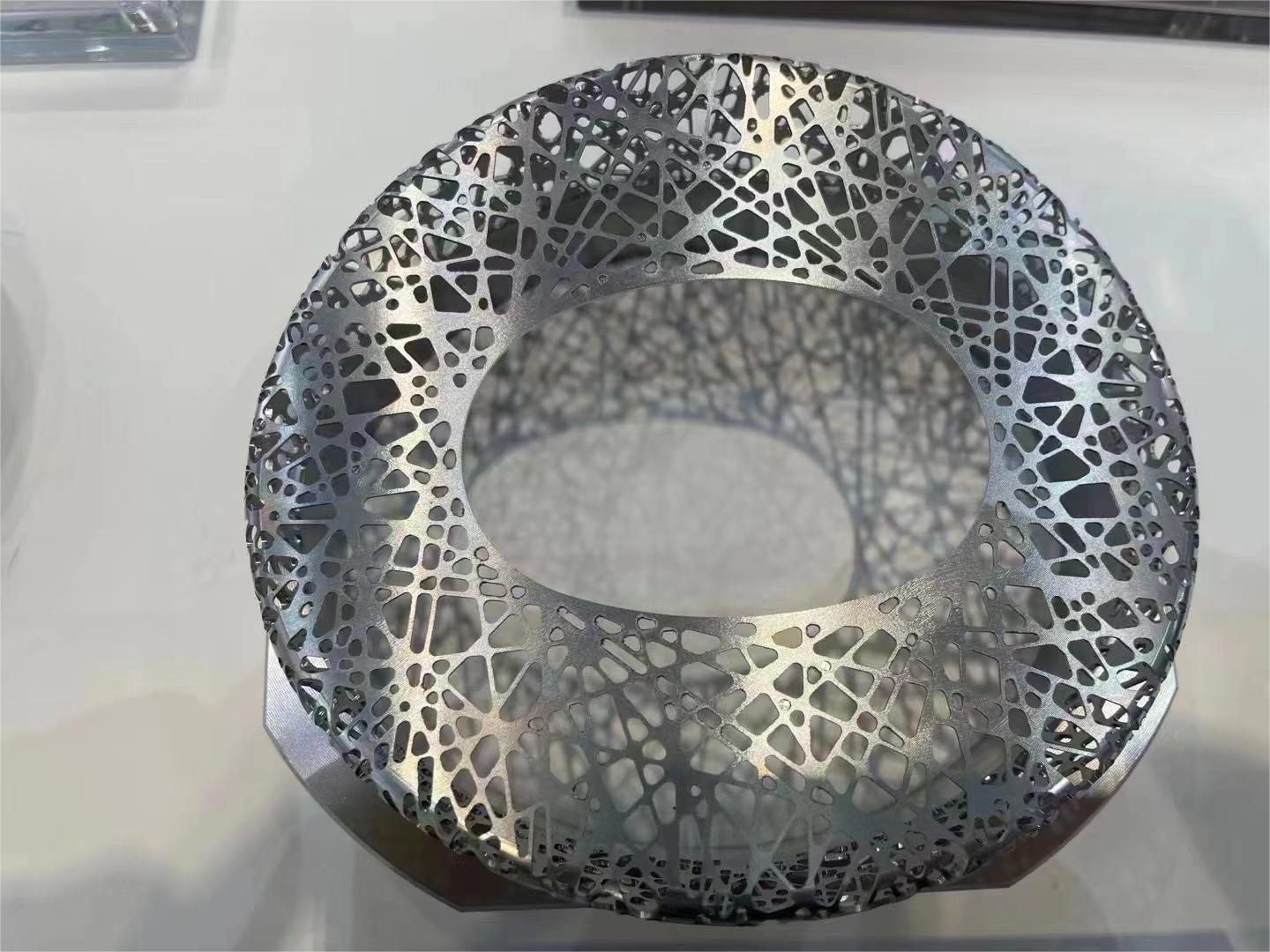

4.3D Printing:3D printing is a method of stacking materials layer by layer to create objects. It is capable of manufacturing prototypes of various shapes with high precision and complexity, so it is widely used in rapid prototyping.

5.Die Casting: Die casting, or pressure casting. Its characteristic is to use the inner cavity of the mold to apply high pressure to the molten metal. Molds are typically machined from stronger alloys, a process somewhat similar to injection molding.

Advantages of rapid prototyping include:

1. Accelerate the product development cycle: Rapid prototyping can quickly generate physical samples during the product design stage, helping the design team discover problems in time and improve the design, thereby shortening the product development cycle.

2. Reduce development costs: Rapid prototyping is often more cost-effective than traditional manufacturing methods, especially when low-volume prototypes need to be manufactured.

3. Improve design quality: By actually inspecting prototypes, design teams can more accurately evaluate the functionality, performance, and appearance of the product, thereby improving design quality.

4. Support customized production: Rapid prototyping technology can flexibly respond to various customized needs and provide customers with personalized solutions.

In general, rapid prototyping is an important part of the modern product development process and can help companies transform ideas into actual products on the market faster and more flexibly.