Dei Casting Moulding

Overview of the die-casting mold design process:

1.An overview of the die-casting mold design process first follows the material category used in the product;

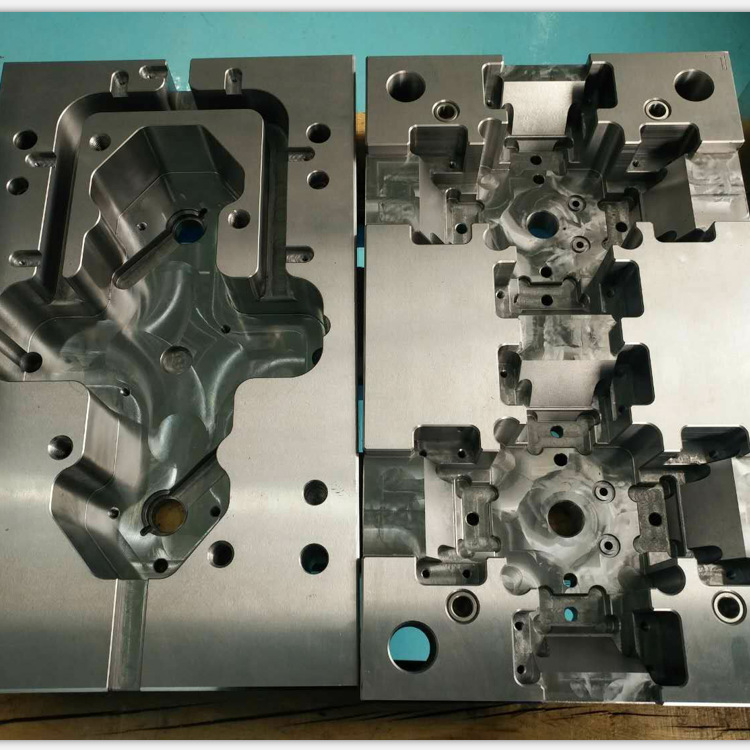

2.Conduct process analysis on the product's shape, accuracy and other indicators to determine the process;

3.Then determine the position of the product in the mold cavity and make the parting surface;

4.Analysis and design of overflow systems and pouring systems;

5.Then design the core assembly and fixation methods for each activity;

6.Next is the design of core pulling distance and force;

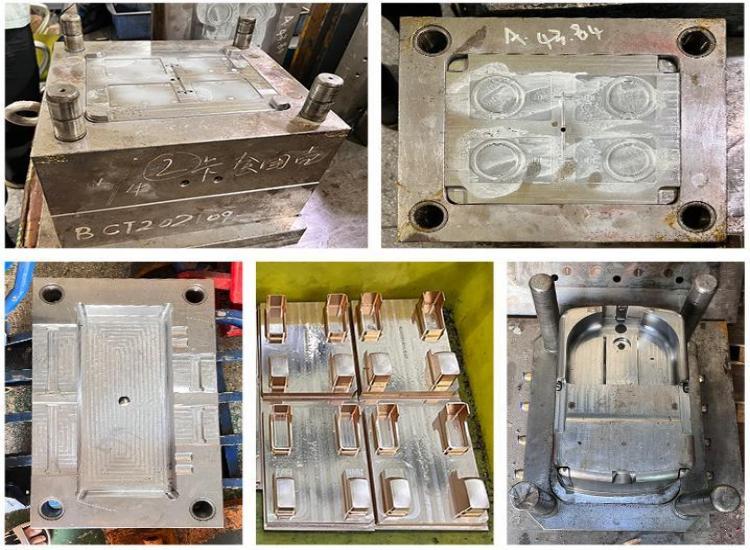

7.The design of the ejection mechanism;

8.To determine the die casting machine, design the mold base and cooling system;

9.Then check the relevant dimensions of the mold and the die-casting machine, and draw process drawings of the mold and each component; Then the design is completed.

10.Die-casting mold processing and polishing is a process that helps the mold to be produced smoothly and is very important for demoulding.