Making a 3D printed mesh

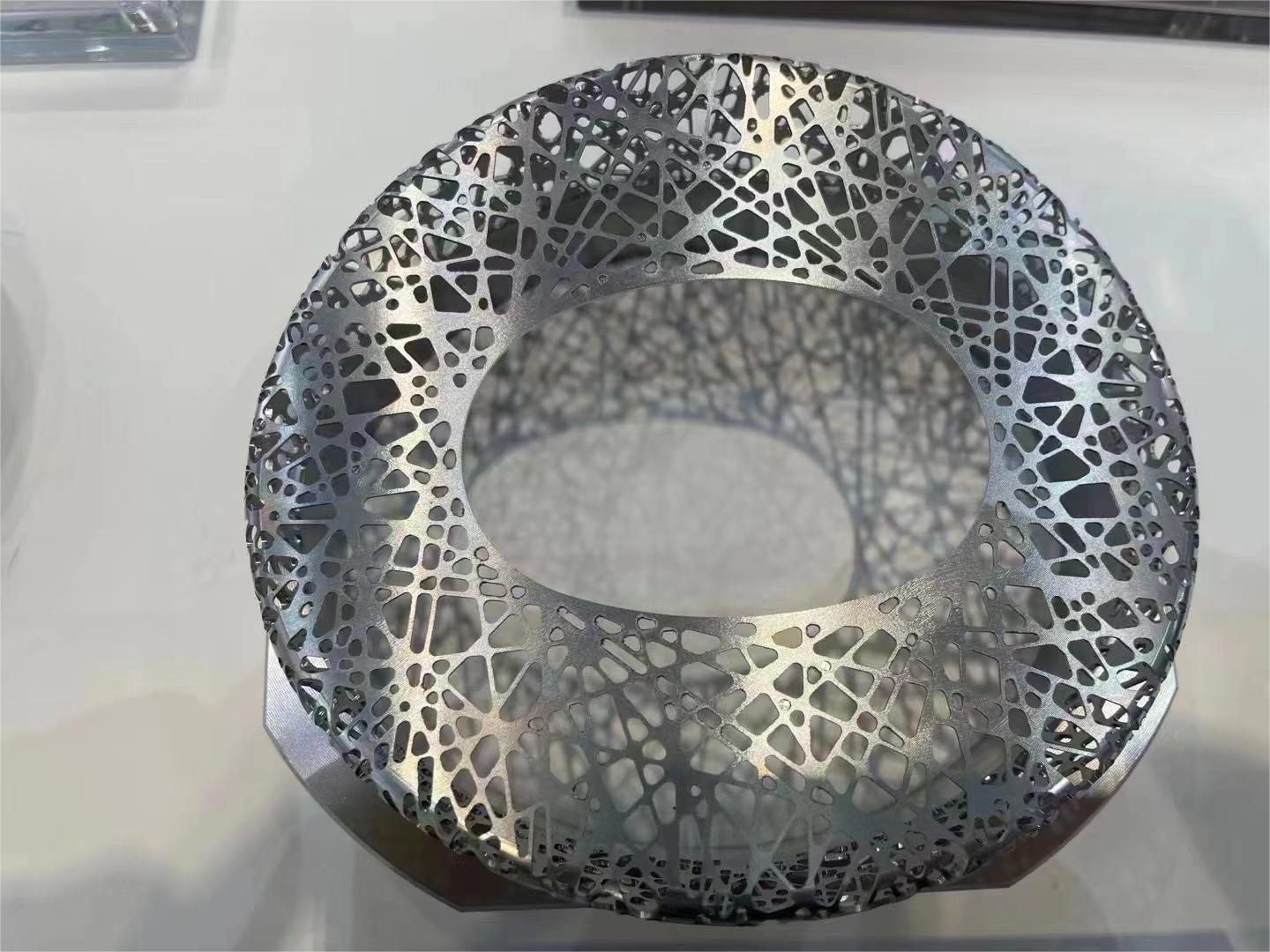

Making 3D printed mesh boxes is a common application, and such boxes are often lightweight, ventilated, and structurally stable. Here are the general steps for making a 3D printed mesh box:

1. Check the model: Use computer-aided design (CAD) software to check the 3D model of the grid box. During the design process, the size, structure, grid size, connection method, etc. of the box need to be considered.

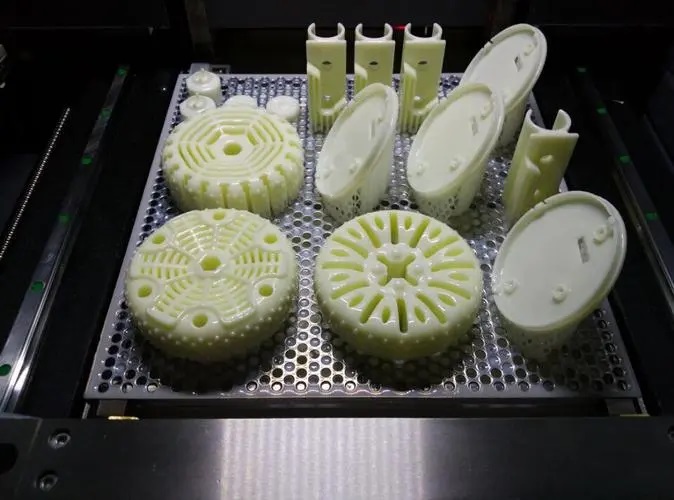

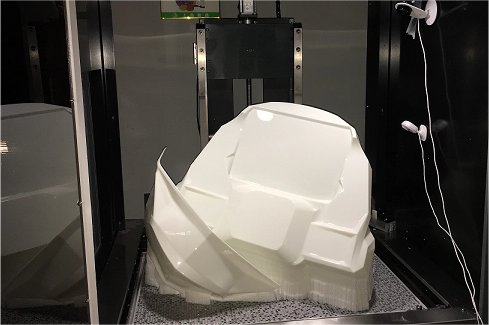

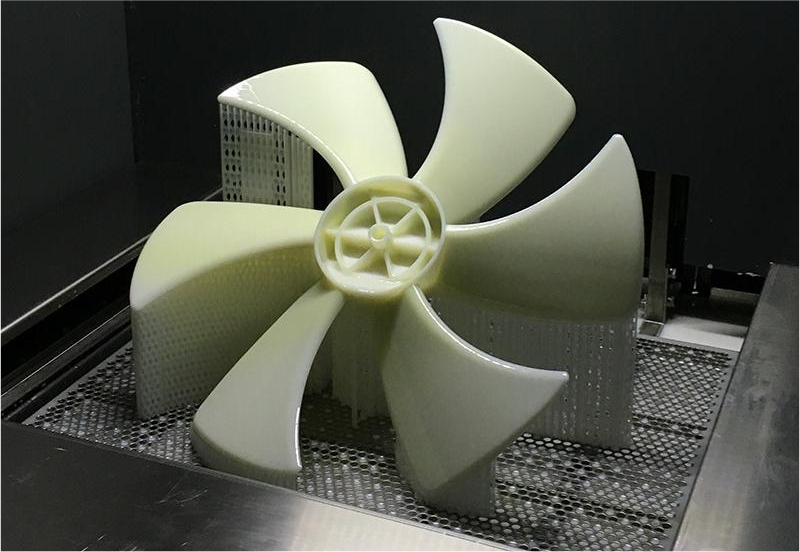

2. Select printing technology and materials: Select SLS’s 3D printing technology and printer model suitable for printing grid boxes. Ruiyi’s commonly used 3D printing technologies include FDM, SLA, SLS, etc. Choose appropriate printing materials according to design requirements, such as PLA, ABS, PETG, nylon, etc.

3. Adjust parameters: According to the selected printing technology and materials, adjust the printing parameters, including layer height, fill rate, printing temperature, etc. For grid-structured boxes, the fill rate is usually set lower to save material and printing time.

4. Print the grid: Import the designed 3D model into the 3D printer and start printing the grid box. During the printing process, the 3D printer stacks molten printing material layer by layer, gradually forming the structure of the box.

5. Post-processing: After printing is completed, some post-processing steps may be required, such as removing support structures, cleaning the surface, trimming edges, etc. These steps help ensure that the printed boxes have good surface quality and dimensional accuracy.

6. Quality inspection: Conduct quality inspection on the printed grid box to ensure that its size, structure and surface quality meet the design requirements. Check whether the connection parts of the box are tight and whether there are any cracks or defects.

7. Application: Use the printed grid boxes in practical application scenarios, such as storage, display, transportation, etc. According to actual needs, the grid can be decorated, painted or otherwise processed.

The production of 3D printed grid boxes can be customized and designed according to personal needs, and has the advantages of high design freedom, short manufacturing cycle, and low cost. It is suitable for various scenarios, such as homes, offices, factories, etc., and can meet different storage and display needs.