Plastic takeover SLA printed

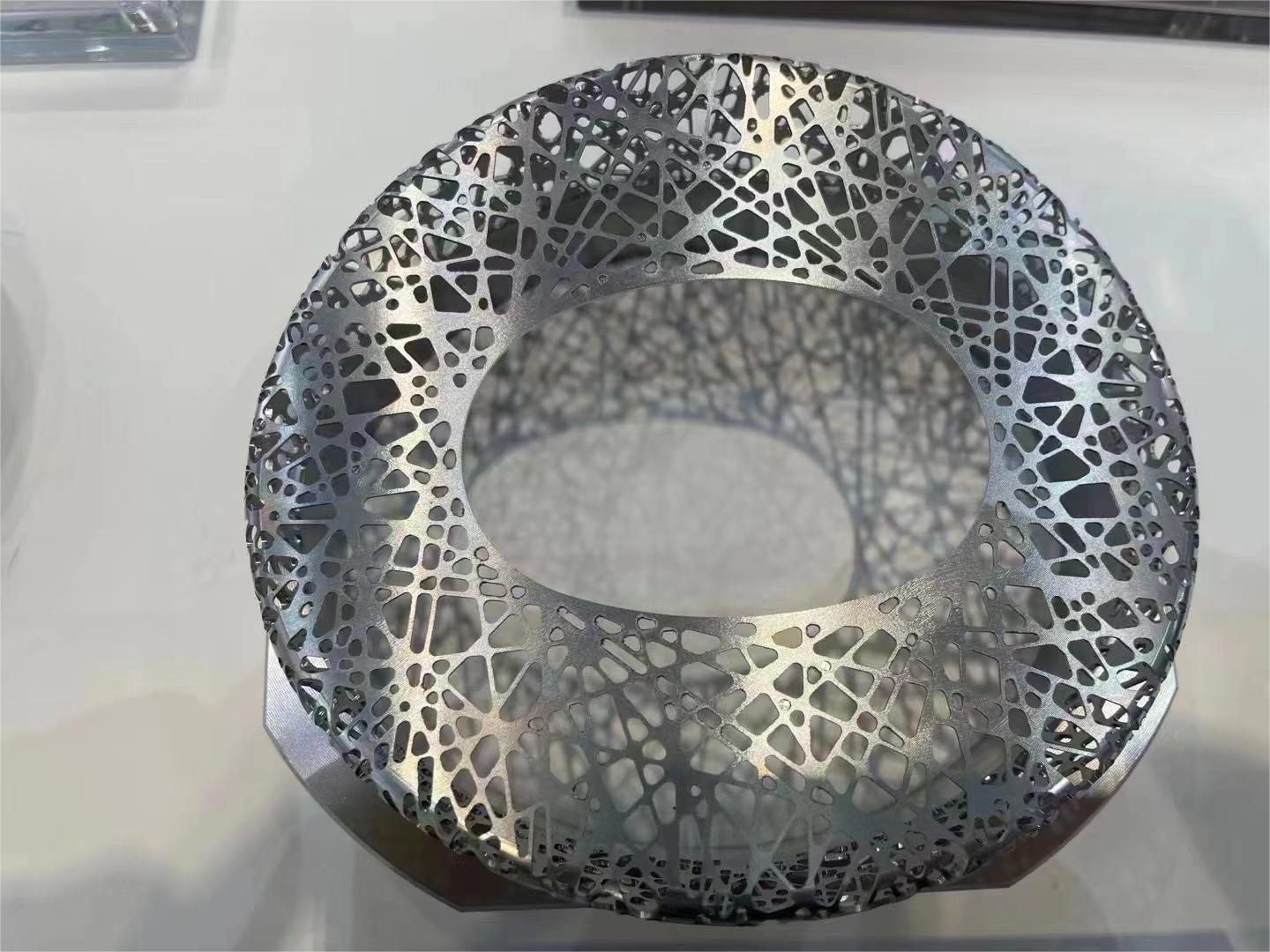

The advantages of 3D printed plastic pipes include high design freedom, short manufacturing cycle, strong customization, etc., and are suitable for small batch production and personalized customization needs. However, it should be noted that 3D printed plastic nozzles may have some limitations, such as dimensional accuracy, high temperature resistance, corrosion resistance, etc., so various factors need to be considered when selecting materials and design.

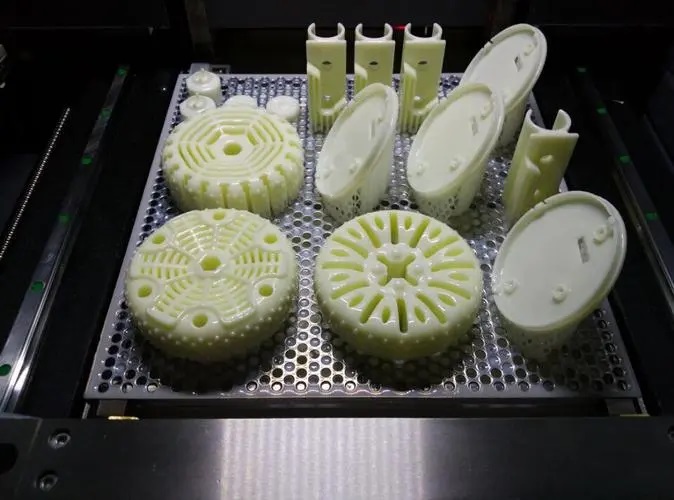

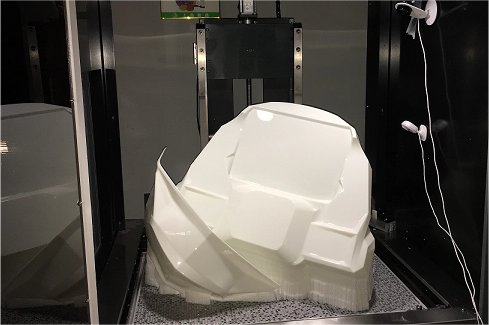

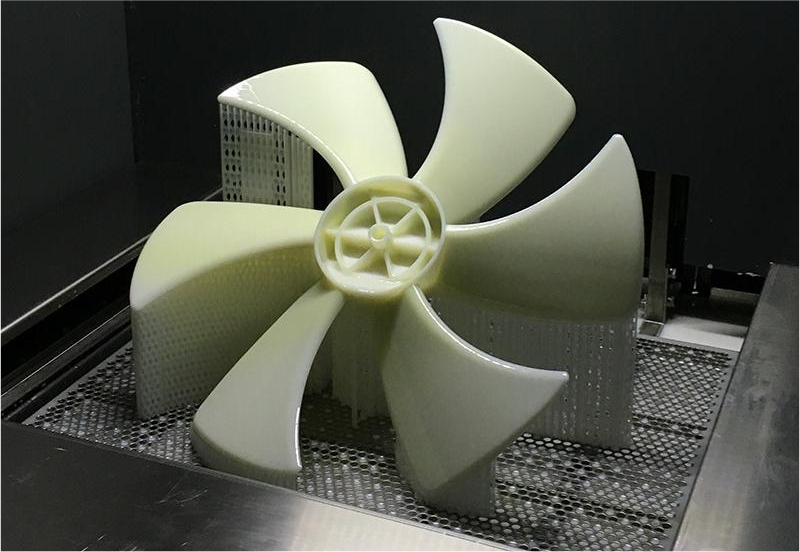

Print the takeover: Import the designed 3D model into the 3D printer and start printing the plastic takeover. During the printing process, the 3D printer stacks molten plastic material layer by layer, gradually forming the shape of the tube.

Post-processing: After printing is completed, some post-processing steps are required, such as removing support structures, cleaning the surface, trimming edges, etc. These steps help ensure that the printed nozzles have good surface quality and dimensional accuracy.

Quality inspection: Conduct quality inspection on the printed plastic nozzles to ensure that their size, wall thickness and surface quality meet the design requirements. Check whether the connection part of the pipe is complete and whether there are cracks or defects.