CNC Machining in Consumer Electronics Industry

The consumer goods industry is a huge industry, covering a variety of products and services that are closely related to consumers' daily lives. In the consumer goods industry, as consumer demands continue to change and upgrade, products are required to be continuously innovated and turnover times shortened. Then Ruiyi provides CNC machining, injection molding, 3D printing, and sheet metal prototyping services have become the only choice for designers to complete rapid prototyping and concept verification.

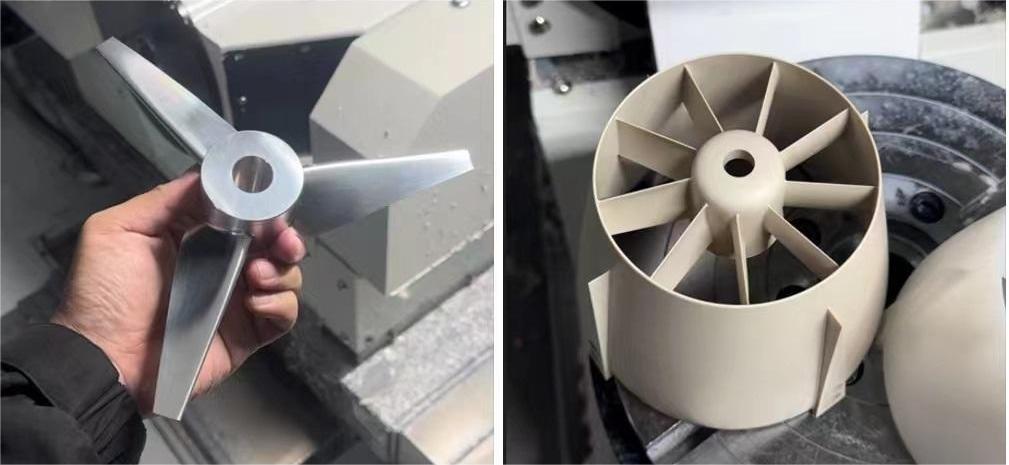

01. CNC machining is widely used in the consumer goods industry. CNC machining technology can achieve high-precision and high-efficiency production, so it has been widely used in the consumer goods industry.

Product shell manufacturing: CNC processing technology can be used to manufacture the shells of various consumer products, such as mobile phones, tablets, game consoles, TVs, etc. These shells usually need to be processed using materials such as metal and plastic. CNC processing technology can achieve high-precision, high-efficiency cutting, drilling, milling and other processing processes to create shells that meet the design requirements.

Component Manufacturing: Many components in consumer products can also be manufactured using CNC machining technology. For example, engine parts and transmission parts in vehicles such as cars and motorcycles can be manufactured with high precision and efficiency through CNC processing technology.

Mold Manufacturing: In the consumer goods industry, molds are an important tool for manufacturing products. CNC machining technology can be used to manufacture various molds, such as injection molds, die-casting molds, etc. These molds can be used to produce a variety of consumer products such as plastic containers, automotive parts, and more.

In short, CNC processing technology is widely used in the consumer goods industry and can be used to manufacture casings, parts and molds for various consumer goods. The high-precision and high-efficiency characteristics of CNC processing technology make consumer goods manufacturing faster and more accurate, thereby improving production efficiency and product quality.

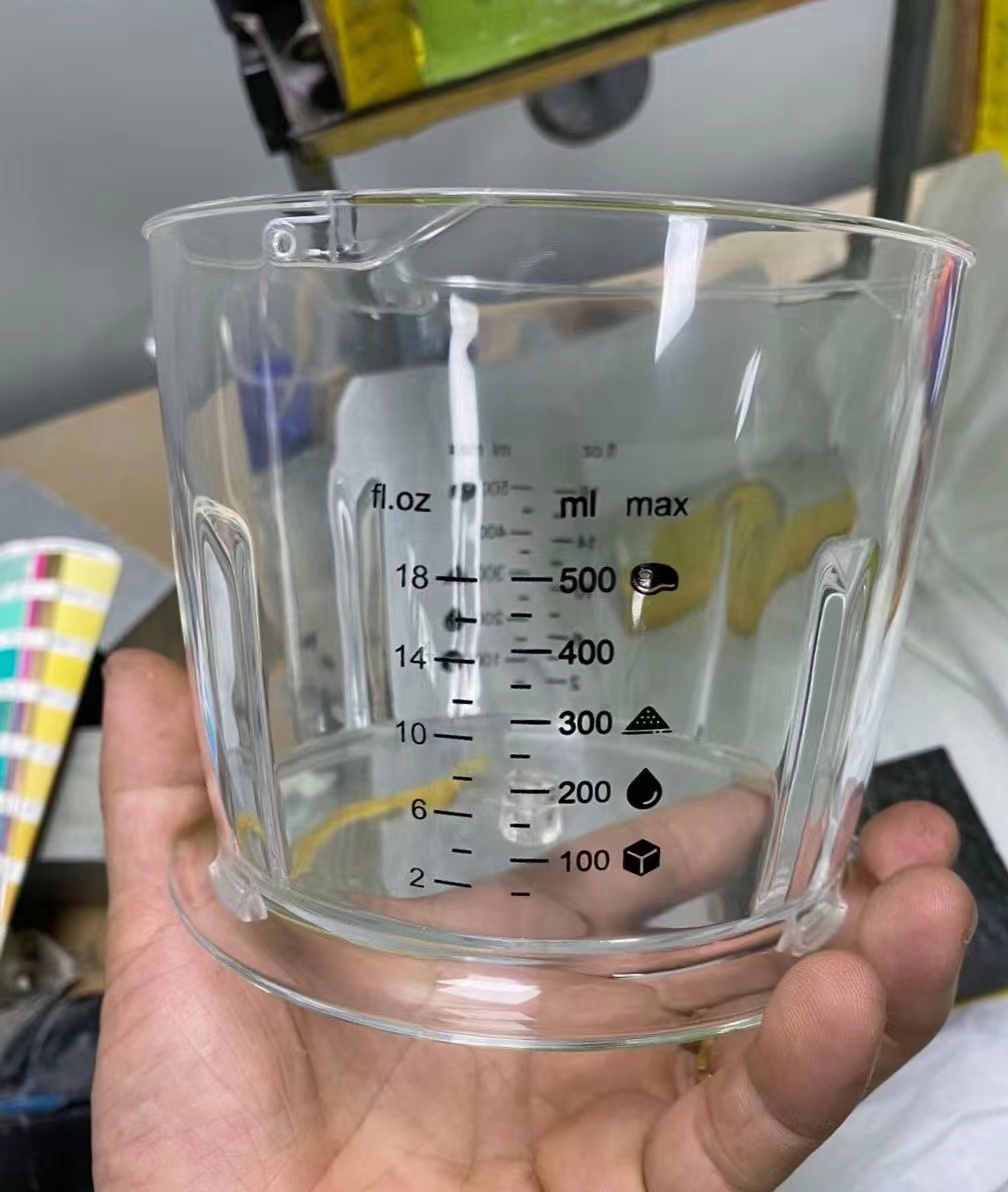

02. Injection molding has a wide range of applications in the consumer goods industry. Injection molding is a production method in which the plastic is heated and plasticized, then injected into the mold cavity through an injection molding machine, and then cooled, solidified, and demoulded to obtain a plastic product of the desired shape.

Plastic parts and products: plastic bottles, toys, shoe soles, tableware, packaging containers, etc.

People's daily lives: beverage bottles, food packaging, kitchen utensils, bathroom supplies, etc.

Electronic products: injection molding is used to manufacture various housings, components, connectors, etc.

In short, injection molding is widely used in the consumer goods industry and involves all aspects of people's lives. The continuous development and improvement of injection molding technology has continuously improved the quality and performance of plastic products, meeting people's growing consumer needs.

03. 3D printing technology in the field of consumer goods is growing rapidly, bringing revolutionary changes to personalized customization and rapid prototyping. Here are some specific examples of 3D printing in consumer product applications:

Personalized customization: 3D printing technology can quickly produce products according to consumers' individual needs. For example, consumers can customize unique shoes, jewelry, glasses, etc. to satisfy their pursuit of personalized products. This kind of personalization not only reduces production costs and inventory costs, but also improves product quality and accuracy.

Toy and animation industry: Designers can use 3D printers to quickly produce scenes and characters in cartoons, allowing animation fans to directly print out their favorite cartoon characters. In addition, 3D printing also provides toy manufacturing companies with a more efficient product development method, reducing product development cycles and costs.

Furniture products: No matter how complex the furniture product is, 3D printers can design furniture models and directly print out furniture prototypes. This not only greatly shortens product design time and improves production efficiency, but also provides consumers with more diverse furniture choices.

Jewelry and Creative DIY: 3D printing technology can accurately manufacture jewelry and other creative DIY works, providing consumers with more unique and customized options.

3D printing technology in the field of consumer goods is constantly expanding. With the continuous advancement of technology and the reduction of costs, the application of 3D printing in the field of consumer goods will become more extensive and in-depth.

04. Sheet metal prototypes are widely used in the consumer goods industry. Sheet metal processing refers to processing metal materials such as metal plates or metal profiles into parts or components through cutting, stamping, forming and other methods. It has the characteristics of light weight, high strength, good conductivity, low cost, and good mass production performance. These characteristics make sheet metal processing products widely used in the consumer goods industry.

Electronic products: The casings and internal structures of many electronic products are made of sheet metal processing. For example, computer cases, mobile phone cases, tablet cases, TV cases, etc. Sheet metal processing enables the precise manufacturing of these casings, ensuring the appearance and quality of the product.

Communication equipment: Sheet metal processing is also widely used in the field of communication equipment, such as mobile phones, telephones, routers, etc. These devices require precise metal parts and structures to ensure performance and stability, and sheet metal processing can achieve these requirements.

Household appliances: Household appliances such as refrigerators, washing machines, air conditioners, etc. also require a large number of sheet metal processing products. For example, the shell of the refrigerator, the door panel of the washing machine, the air vent of the air conditioner, etc. are all made of sheet metal processing.

With the continuous advancement of science and technology and the continuous improvement of consumer demand, the application of sheet metal processing in the consumer goods industry will become more extensive and in-depth.