CNC machining Aerospace industry parts

CNC machining Aerospace industry parts

CNC machining has been an active part of the aerospace industry since the early days of flight. The aerospace industry needs accurate and high-quality parts for aircraft designs, and CNC machining provides just that. Let's take a look at some of the most common aerospace applications for CNC machined parts.

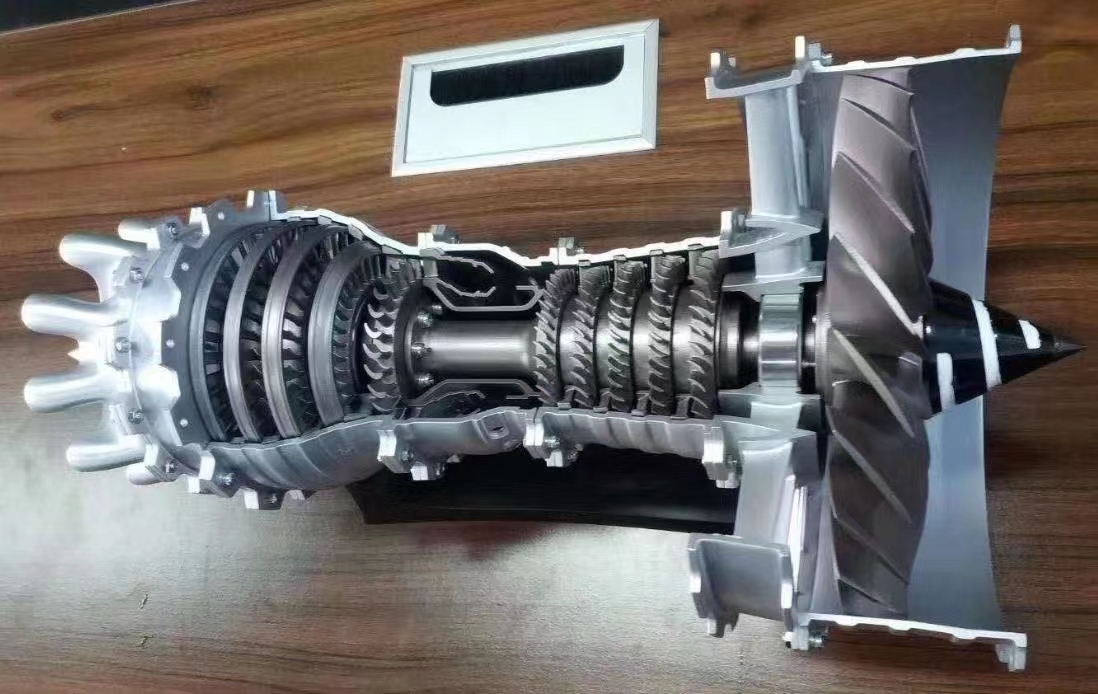

1. Aircraft Components

CNC machining technology is critical to the manufacture of a large number of aircraft parts, such as turbines, casings, enclosures, and other components. These parts require extreme precision, quality and consistency, making CNC machining the perfect method of choice. Designers and engineers in the aerospace industry can easily come up with complex and unique designs that complement CNC machining technology.

2. Aerospace structures

CNC machining is used to create aerospace structures such as wings, fuselages and frames. The technology used in CNC machining is ideal for creating the complex fixtures and shapes required for aircraft manufacturing. CNC machines can also provide shapes and forms that are not possible with traditional machining.

3. Aerospace prototyping

Prototyping is an important part of almost all engineering disciplines. Rapid prototyping is the process of creating models quickly and accurately. Designers and engineers in the aerospace industry use CNC machining to produce high-quality rapid prototypes easily, accurately and quickly. As a result, CNC machining technology allows designers to modify, upgrade, and adapt prototypes as needed.

4. Aerospace Tooling

CNC machining is also used to manufacture aerospace tools such as jigs, fixtures and inspection gauges. These tools require the highest level of precision and consistency, which CNC machining technology provides. CNC machines can easily cut and produce customised components that meet the necessary requirements.

5. Satellite components

Another important aerospace application for CNC machining is the production of satellite components. The production of satellite components requires a high level of precision, which is where CNC machining comes in. Satellites also require lightweight materials, and CNC machining can be combined with 3D printing to create components that are both lightweight and precise.

Conclusion:

CNC machining has been vital in the aerospace industry since the beginning of flight. The use of CNC machining technology has enabled designers and engineers to create high-quality, accurate and consistent components that meet stringent safety requirements and limit production time. In conclusion, CNC machining technology will continue to be an important part of the aerospace industry in many ways because of its versatility, accuracy and reliability. As technology advances, it can only get better at providing CNC machined parts for aerospace applications.