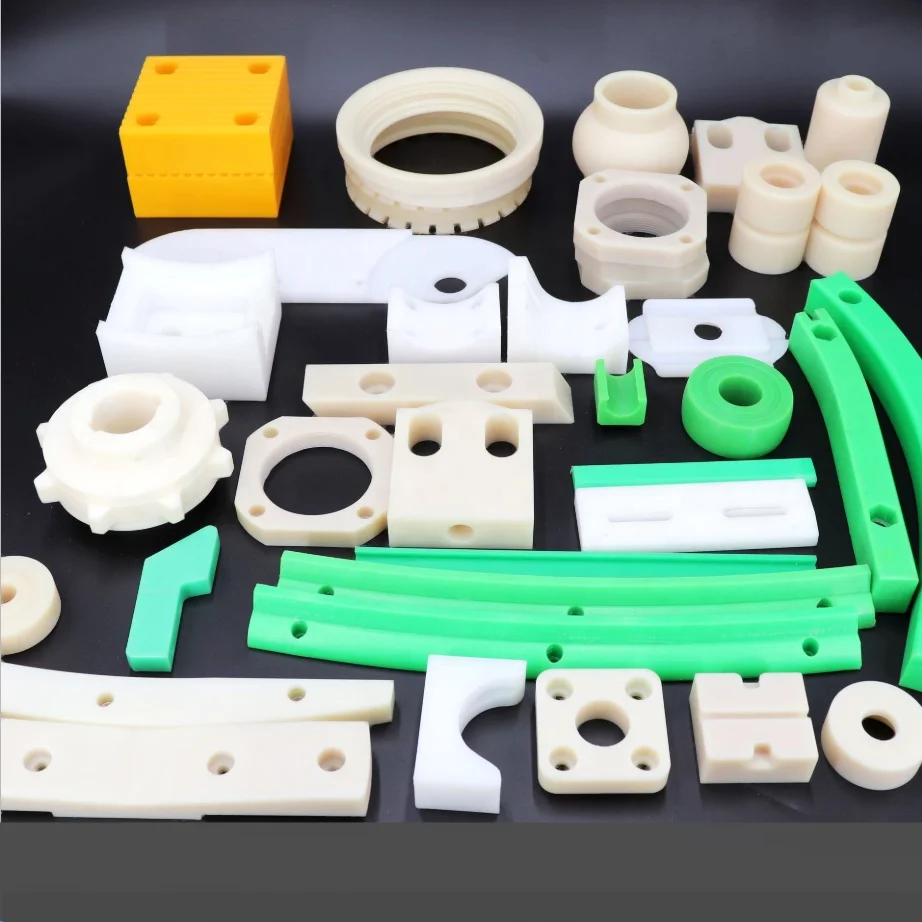

CNC Plastic

CNC Plastic Parts OEM

Material: ABS/POM/Nylon/PMMA/PEEK/PC/PP, etc.

Process: CNC milling, CNC turning, CNC drilling

Finish: /

Quantity: 1/100/500/1000

Production Time: 2/5/10 Business days

Drawing:2D(CAD, PDF), 3D(STP, STEP)

Product Parts Category: Precision CNC Machining Parts

The process of CNC processing plastic parts is as follows

First, communicate with the customer to confirm the design requirements of the plastic parts, including size, shape, material selection, etc. Discuss drawing design details and special requirements to ensure the final product meets customer expectations.

Based on the design drawings and 3D models provided by the customer, create CNC machine tool programs for processing and prepare corresponding tools.

Spare materials: Select corresponding materials according to customer requirements. Commonly used plastic materials include ABS, PVC, PP, PC, PMMA, PEEK, POM, etc.

Processing process: According to the pre-made processing program, plastic blocks or plates are cut, milled, turned, etc., and processed into final parts.

Surface treatment of plastic parts according to customer needs. This may include processes such as grinding, polishing, and painting to improve appearance and surface quality.

Strict quality control procedures are conducted to ensure that processed plastic parts meet design specifications and quality standards. Use measuring equipment such as 2D inspection, calipers, plug gauges, height instruments, vernier calipers, block gauges, etc. for dimensional inspection and visual inspection for quality inspection.

Finally, there is the assembly work of plastic parts, assembling different parts into finished products. Once completed, the finished product is packaged to ensure safe transportation and storage.

Deliver the processed plastic parts to customers and provide necessary after-sales service and support. This includes responding promptly to customer questions and feedback to ensure customer satisfaction.