Assembly Service

Assembly prototype is the assembly of different parts or components according to design specifications and engineering drawings to create a preliminary sample or model of the product. Here are the general steps for making an assembled prototype:

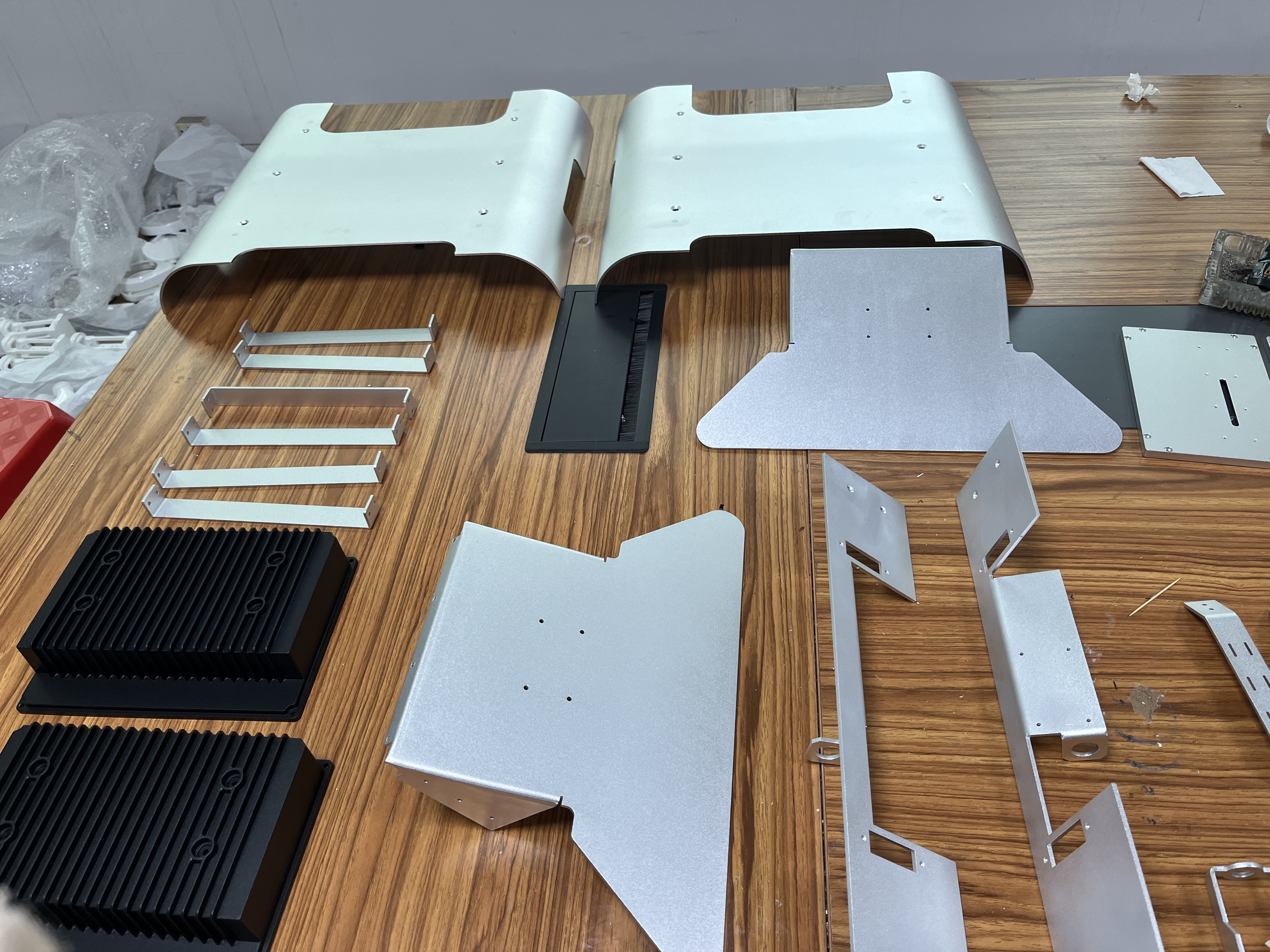

1. Preparation:

Prepare all required parts, components, tools and materials, as well as corresponding design documents and engineering drawings. Ensure the quality and dimensions of all parts and assemblies meet specifications.

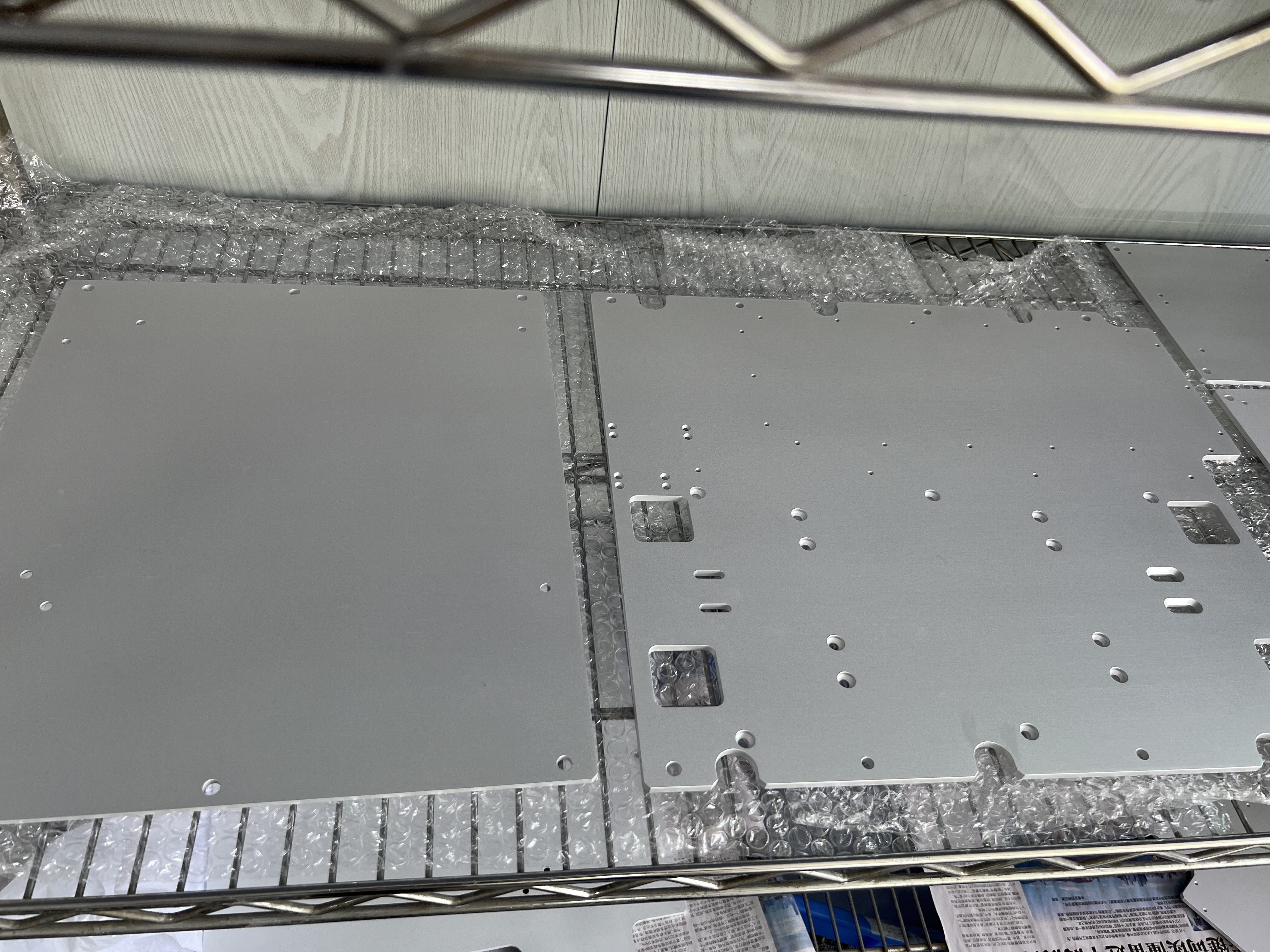

2. Component cleaning:

Clean all parts and components and ensure their surfaces are clean and dust-free to ensure quality and precision during assembly.

3. Assembly sequence planning:

Read the design documents and engineering drawings carefully to understand the sequence and method of assembly. According to the assembly steps, plan the assembly sequence to ensure that it is assembled in the correct order to avoid problems or errors.

4. Part matching and adjustment:

Check the fit of all parts and components to ensure they fit accurately and connect seamlessly. If necessary, make adjustments or trims to the parts to ensure they fit together correctly.

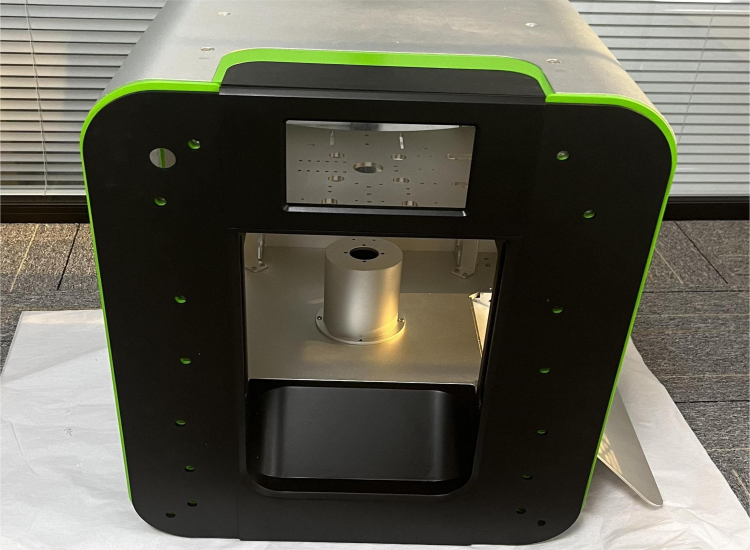

5. Assembly process:

Assemble parts and components step by step in a planned sequence, using appropriate tools and methods for assembly. Make sure every step is done correctly and that every part is installed and secured correctly.

6. Quality control:

Perform quality control during assembly, checking each assembly step for accuracy and completeness.

Assembled components are inspected using measuring tools and inspection equipment to ensure that their dimensions and functionality meet design requirements.

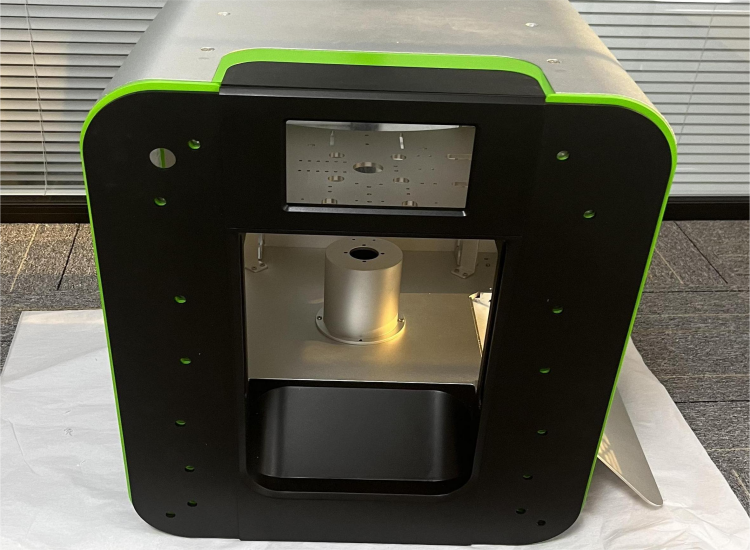

7. Testing and verification:

After assembly is complete, the prototype is functionally tested and verified.

Ensure that the prototype functions and performs as expected and documents test results and any issues found.

8. Adjustments and corrections:

Make necessary adjustments and corrections to the prototype based on test and validation results. Correct any discovered issues or flaws and ensure the final version of the prototype meets design requirements.

9. Final review:

Conduct final reviews and reviews to ensure assembled prototypes meet all design and performance requirements. Confirm that the prototype can be used as a sample for further production or testing, and make corresponding records and documents. Through the above steps, high-quality assembly prototypes can be produced to evaluate the design, functionality and performance of the product, and lay the foundation for subsequent production and development work.