CNC POM

Material: POM (is used in medical, industrial equipment and other industries.)

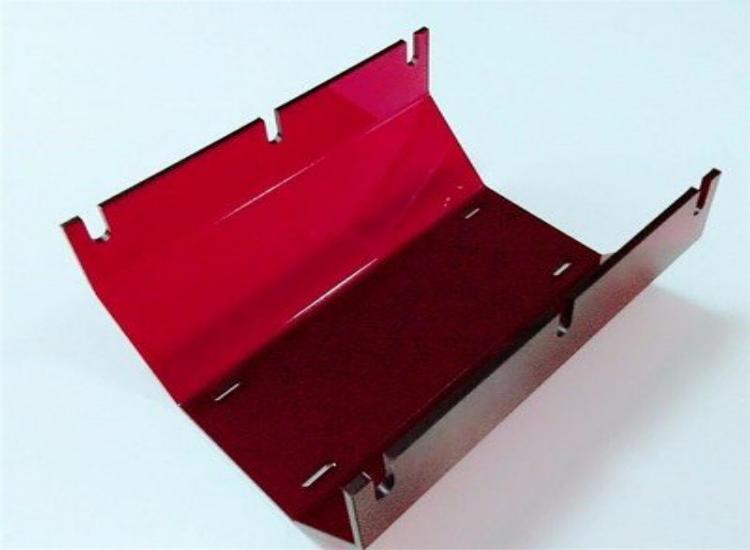

Process: CNC milling, CNC turning, CNC drilling

Drawing:2D(CAD, PDF), 3D(STP, STEP)

POM is an engineering thermoplastic with a density between 1.410 and 1.420 g/cm3. It is a material with extremely high machinability among engineering thermoplastics. It is known for its high precision, high stiffness, low friction, excellent high temperature, dimensional stability, and extremely low water absorption.

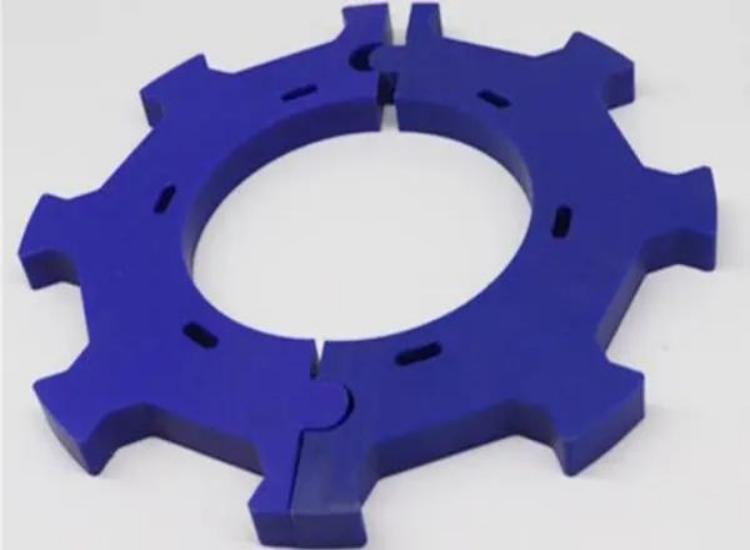

Wear resistance and impact resistance: POM has excellent wear resistance and impact resistance, so it is often used in the manufacture of mechanical parts, such as gears, bearings, sliding bearings, racks, pins, etc. Its low coefficient of friction and self-lubricating properties allow it to perform well at high speeds and loads.

High temperature resistance: POM can maintain its physical properties at higher temperatures and is suitable for automotive parts manufacturing, such as brake systems, oil pump parts, transmission system parts, door handles, interior trim parts, etc. Its wear and oil resistance make it a common choice in the automotive industry

Diverse machining methods: POM can be machined via standard CNC machining methods, or pre-machined POM parts can be annealed to improve their machinability.